-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

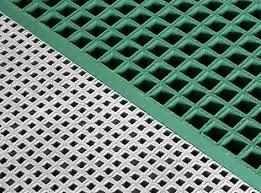

fiberglass vessels and tanks

The Versatility of Fiberglass Vessels and Tanks

Fiberglass has revolutionized various industries, primarily due to its strength, durability, and resistance to corrosion. When it comes to vessels and storage tanks, fiberglass stands out as a preferred choice for both industrial and recreational applications. This article explores the advantages of fiberglass vessels and tanks, their applications, and the reasons behind their growing popularity.

One of the most notable properties of fiberglass is its lightweight design. Compared to traditional materials like steel or aluminum, fiberglass vessels can be constructed to be significantly lighter, resulting in higher fuel efficiency and lower transportation costs. This attribute is particularly appealing to the marine industry, where weight plays a critical role in performance. Fiberglass boats, whether for fishing, sailing, or leisure, offer a combination of maneuverability and speed that is hard to match.

Another significant advantage of fiberglass is its resistance to environmental factors. Fiberglass does not corrode, unlike metal vessels, which can deteriorate over time when exposed to saltwater or chemicals. This characteristic makes fiberglass an ideal choice for storage tanks as well, especially in industries dealing with corrosive substances, such as chemicals or wastewater. With the ability to withstand harsh environments, fiberglass tanks require less maintenance, leading to long-term savings for businesses.

fiberglass vessels and tanks

Moreover, fiberglass is customizable, enabling manufacturers to produce tanks and vessels in various shapes and sizes to meet specific needs. This flexibility is crucial for applications ranging from agricultural storage tanks for fertilizers and chemicals to marine vessels designed for specialized tasks like research and oceanographic studies. Manufacturers can engineer fiberglass products to include multiple features, such as internal linings for additional durability or insulation for temperature control.

The infusion of technology in manufacturing processes has further enhanced the properties of fiberglass vessels and tanks. Advanced composite materials allow for the development of stronger, more resilient products that can endure extreme conditions. The combination of fiberglass with other materials like carbon fiber or aramid fibers leads to improved performance metrics, paving the way for innovations in design and functionality.

Safety is another critical consideration in the use of fiberglass. Unlike metal, fiberglass does not pose a significant risk of explosion or fire when dealing with flammable substances, adding an extra layer of safety for users. Additionally, fiberglass vessels and tanks can be designed with built-in safety features such as overflow alarms and leak detection systems, ensuring optimal operational safety.

In conclusion, fiberglass vessels and tanks offer exceptional benefits, including lightweight design, corrosion resistance, customization, advanced technology integration, and enhanced safety features. Their applications are vast, ranging from marine uses, such as boats and yachts, to industrial applications like chemical and water storage. As industries continue to seek durable, efficient, and safe alternatives to traditional materials, fiberglass is set to maintain its position as a vital resource. The growing demand for fiberglass infrastructure reflects its successful integration into modern technology and industry, promising a future filled with potential advancements and innovations. Whether on the sea or in industrial settings, fiberglass vessels and tanks are indeed a testament to material science's evolving capabilities.