-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 20, 2025 15:41

Back to list

Duct System

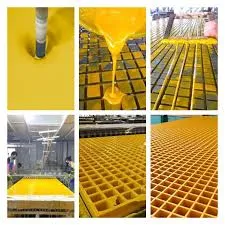

When it comes to creating efficient water management systems, fiberglass weirs have become a pivotal component thanks to their exceptional durability, flexibility, and resistance to environmental elements. Made from reinforced composite materials, fiberglass weirs stand out due to their robust properties. This sets them apart from traditional materials like concrete and steel, which are susceptible to wear over time.

In terms of design flexibility, fiberglass weirs offer a wide array of possibilities. Manufacturers have the capability to produce weirs of various shapes and sizes tailored to specific project requirements. This adaptability allows engineers to address unique challenges, such as designing weirs for sites with irregular flow patterns or installation areas with limited access. Expert users of fiberglass weirs attest to their superior performance in prolonged applications. Fiberglass remains unaffected by biological growth, a common problem in aquatic installations. This feature ensures that over time, performance remains steady and system efficiency does not degrade. Consequently, industries dealing with aquatic life conservation or irrigation can rely on these weirs for consistent results. Authored by seasoned engineers specializing in material sciences, extensive research has corroborated the superior life span and reliability of fiberglass weirs. Academic publications support the fact that fiberglass materials maintain their physical and chemical properties even under extreme conditions, underscoring their credibility for long-term projects. Trust in fiberglass weir applications stems not only from empirical data but also from the myriad testimonials from professionals in multiple sectors. Water resource management experts frequently share their successful implementation stories, enhancing the perceived value and dependability of these materials. For any entity considering the adoption of fiberglass weirs, the decision translates to investing in a future-proof solution that aligns with both environmental and economic goals. Fiberglass weirs promise a seamless integration with existing structures while offering a modern solution that is prepared to meet the challenges of tomorrow. They demonstrably enhance system efficiency, cut costs, and uphold sustainability, making them a preferred choice across diverse water management applications.

In terms of design flexibility, fiberglass weirs offer a wide array of possibilities. Manufacturers have the capability to produce weirs of various shapes and sizes tailored to specific project requirements. This adaptability allows engineers to address unique challenges, such as designing weirs for sites with irregular flow patterns or installation areas with limited access. Expert users of fiberglass weirs attest to their superior performance in prolonged applications. Fiberglass remains unaffected by biological growth, a common problem in aquatic installations. This feature ensures that over time, performance remains steady and system efficiency does not degrade. Consequently, industries dealing with aquatic life conservation or irrigation can rely on these weirs for consistent results. Authored by seasoned engineers specializing in material sciences, extensive research has corroborated the superior life span and reliability of fiberglass weirs. Academic publications support the fact that fiberglass materials maintain their physical and chemical properties even under extreme conditions, underscoring their credibility for long-term projects. Trust in fiberglass weir applications stems not only from empirical data but also from the myriad testimonials from professionals in multiple sectors. Water resource management experts frequently share their successful implementation stories, enhancing the perceived value and dependability of these materials. For any entity considering the adoption of fiberglass weirs, the decision translates to investing in a future-proof solution that aligns with both environmental and economic goals. Fiberglass weirs promise a seamless integration with existing structures while offering a modern solution that is prepared to meet the challenges of tomorrow. They demonstrably enhance system efficiency, cut costs, and uphold sustainability, making them a preferred choice across diverse water management applications.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025