-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 08, 2025 01:44

Back to list

fiber pipe

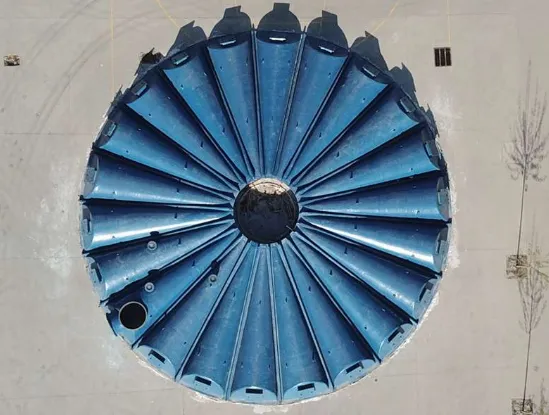

Fiber pipes have emerged as a revolutionary product in the construction and utility sectors, offering a blend of durability, flexibility, and efficiency that is unmatched by traditional piping materials. Unlike conventional pipes made from metal or PVC, fiber pipes are engineered using advanced fiber composite materials, which confer several outstanding advantages that make them ideal for various applications.

From a sustainability perspective, fiber pipes contribute significantly to reducing environmental impact. They have a lower carbon footprint during both manufacturing and operational phases compared to traditional pipes. Many fiber pipe manufacturers incorporate recycled materials in their production processes, further enhancing their environmental credentials. Furthermore, their longevity means fewer replacements and less material wastage over time, aligning with global sustainability goals and the shift towards greener practices in industrial infrastructure development. In terms of expertise, the engineering and development of fiber pipes are backed by extensive research and advanced technology. The composite materials used in these pipes are the outcome of years of scientific advancements in materials science, ensuring that they meet rigorous industry standards for safety and performance. Leading manufacturers maintain stringent quality control checks throughout the production process, reinforcing the dependability and superior quality of their fiber pipe products. For businesses and constructors looking to enhance their credibility and authority in the market, incorporating fiber pipes into their infrastructure projects sends a clear message of commitment to quality and innovation. By adopting cutting-edge materials, companies not only improve their operational efficiency but also gain a competitive edge, as clients and stakeholders increasingly value sustainable and forward-thinking practices. In conclusion, fiber pipes represent the future of industrial piping solutions. With their array of advantages—durability, resilience, cost-effectiveness, and environmental sustainability—they are poised to replace traditional piping materials across numerous sectors. As industries continue to evolve and adapt to new technological advancements, fiber pipes offer a reliable and innovative solution that meets modern-day demands while setting the standard for future industrial infrastructure. Seek out reputable suppliers who prioritize quality, compliance, and customer satisfaction to ensure the best results when implementing fiber pipe systems in your projects.

From a sustainability perspective, fiber pipes contribute significantly to reducing environmental impact. They have a lower carbon footprint during both manufacturing and operational phases compared to traditional pipes. Many fiber pipe manufacturers incorporate recycled materials in their production processes, further enhancing their environmental credentials. Furthermore, their longevity means fewer replacements and less material wastage over time, aligning with global sustainability goals and the shift towards greener practices in industrial infrastructure development. In terms of expertise, the engineering and development of fiber pipes are backed by extensive research and advanced technology. The composite materials used in these pipes are the outcome of years of scientific advancements in materials science, ensuring that they meet rigorous industry standards for safety and performance. Leading manufacturers maintain stringent quality control checks throughout the production process, reinforcing the dependability and superior quality of their fiber pipe products. For businesses and constructors looking to enhance their credibility and authority in the market, incorporating fiber pipes into their infrastructure projects sends a clear message of commitment to quality and innovation. By adopting cutting-edge materials, companies not only improve their operational efficiency but also gain a competitive edge, as clients and stakeholders increasingly value sustainable and forward-thinking practices. In conclusion, fiber pipes represent the future of industrial piping solutions. With their array of advantages—durability, resilience, cost-effectiveness, and environmental sustainability—they are poised to replace traditional piping materials across numerous sectors. As industries continue to evolve and adapt to new technological advancements, fiber pipes offer a reliable and innovative solution that meets modern-day demands while setting the standard for future industrial infrastructure. Seek out reputable suppliers who prioritize quality, compliance, and customer satisfaction to ensure the best results when implementing fiber pipe systems in your projects.

Related Products