-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Techniques for Efficient Flue Gas Desulfurization in Industrial Applications

Flue Gas Desulfurization An Essential Technology for Environmental Protection

Flue gas desulfurization (FGD) is a critical technology employed to reduce sulfur dioxide (SO2) emissions from industrial processes, particularly in power generation and other sectors that burn fossil fuels. As environmental concerns over air quality and climate change have gained prominence, the implementation of FGD systems has become increasingly important. This article explores the significance, methodologies, and advancements in flue gas desulfurization.

Sulfur dioxide, a prominent pollutant, is primarily produced by the combustion of sulfur-containing fuels such as coal, oil, and gas. When released into the atmosphere, SO2 can contribute to the formation of acid rain, which negatively impacts ecosystems, structures, and human health. Additionally, SO2 is associated with respiratory problems and other health issues. Consequently, regulatory agencies worldwide have imposed stringent limits on SO2 emissions, driving the adoption of FGD technologies in various industries.

FGD systems primarily utilize two approaches wet scrubbing and dry scrubbing. Wet scrubbing, the most common method, involves passing flue gas through a slurry of alkaline sorbents, typically limestone or lime. The SO2 in the flue gas reacts with the alkaline material, converting it into gypsum—a valuable byproduct that can be used in construction and other industries. This method boasts high removal efficiency, often exceeding 90%. However, it requires careful management of water usage and waste products.

An alternative approach, dry scrubbing, employs dry reagents such as hydrated lime or sodium bicarbonate to capture SO2 from the flue gas. This method generally produces less wastewater and can be more adaptable to various types of facilities. While the SO2 removal efficiency of dry scrubbing may be lower than that of wet scrubbing, advancements in technology and process optimization continue to enhance its effectiveness.

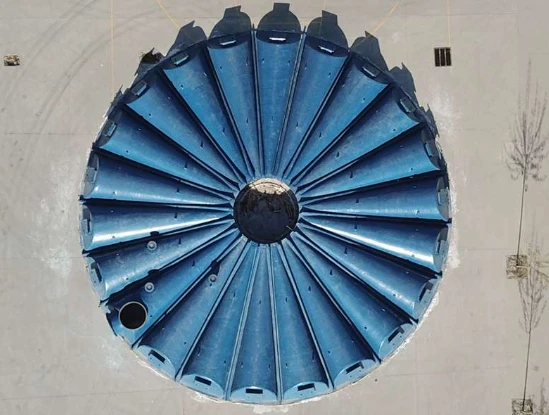

flue gas desulfurization

Recent innovations in flue gas desulfurization have focused on increasing efficiency and reducing costs. For instance, the development of advanced sorbents, such as calcium-based or sodium-based materials, has improved the adsorption capacity and effectiveness of FGD systems. Additionally, integrated FGD systems that combine the desulfurization process with carbon capture have emerged, addressing multiple environmental challenges simultaneously. These systems not only reduce SO2 emissions but also capture carbon dioxide (CO2), contributing to climate change mitigation efforts.

Furthermore, automation and monitoring technologies are transforming the operational landscape of FGD systems. Real-time data analytics allow for better control and optimization of the desulfurization process, leading to enhanced performance and reduced operational costs. Moreover, advancements in artificial intelligence (AI) and machine learning are enabling predictive maintenance, reducing downtime, and ensuring the consistent functioning of FGD systems.

From an economic perspective, the implementation of flue gas desulfurization can also yield significant benefits. By minimizing SO2 emissions, industries can avoid steep fines associated with non-compliance to environmental regulations. Additionally, the production of valuable byproducts, such as gypsum, can create new revenue streams for companies. This not only offsets the operational costs of FGD systems but also contributes to the circular economy by promoting resource recovery.

Despite its importance, the adoption of flue gas desulfurization technologies is not without challenges. The initial capital investment can be substantial, and the need for skilled personnel to operate and maintain these systems can strain some organizations. However, with increasing awareness of environmental issues and the imperative for sustainable practices, many companies recognize the long-term benefits of investing in FGD technology.

In conclusion, flue gas desulfurization is a vital technology for mitigating sulfur dioxide emissions from industrial processes, playing a significant role in efforts to combat air pollution and climate change. As innovations continue to enhance its efficiency and reduce costs, FGD systems will remain indispensable in achieving cleaner air and promoting sustainable industrial practices. The commitment to environmental stewardship underscores the necessity to prioritize technologies like FGD, ensuring a healthier planet for future generations.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025