-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Quality FRP Fittings for Durable Applications

Understanding FRP Fittings The Future of Piping Solutions

Fiber Reinforced Polymer (FRP) fittings have emerged as a transformative solution in various industries, offering a significant advantage over traditional materials such as steel and PVC. With their unique properties, FRP fittings are designed to cater to a broad range of applications, including water treatment, chemical processing, and construction, among others.

FRP fittings are composed of a polymer matrix reinforced with fibers, typically glass or carbon. This composition provides remarkable strength-to-weight ratios, enabling engineers and designers to create lighter structures without compromising integrity. As industries seek to minimize weight without losing performance, FRP has become a popular choice. The lightweight nature of FRP fittings translates to lower transportation costs and easier installation processes, ultimately reducing project timelines and labor costs.

Understanding FRP Fittings The Future of Piping Solutions

Furthermore, FRP fittings exhibit excellent thermal and electrical insulation properties. This makes them particularly advantageous in applications where temperature fluctuations and electrical conductivity are concerns. By minimizing heat transfer and preventing electrical leakage, FRP fittings contribute to both safety and energy efficiency in various systems.

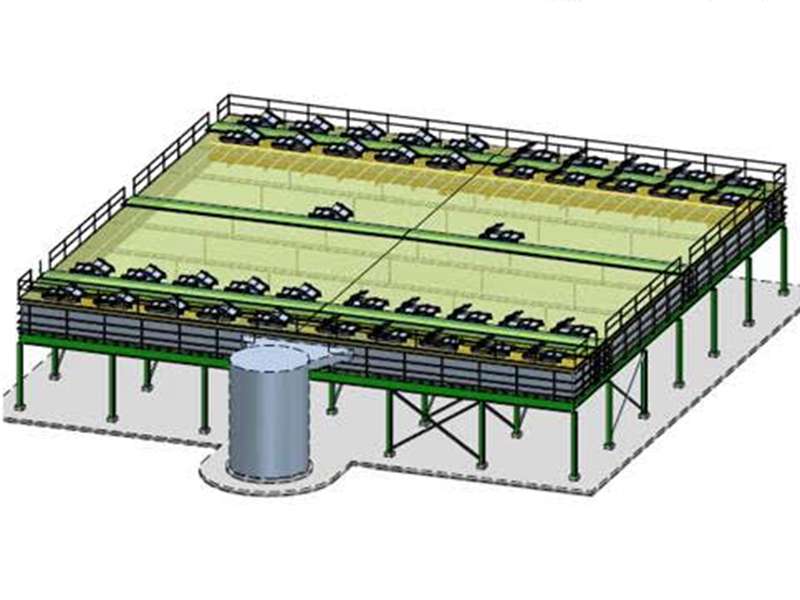

frp fittings

The adaptability of FRP fittings is another key advantage. They can be manufactured in a wide range of shapes and sizes, catering to specific project needs. Customization options allow for tailored solutions that meet unique specifications, making FRP a highly versatile choice for engineers and designers. Additionally, their compatibility with advanced fabrication techniques opens up possibilities for innovative designs that were previously unattainable with traditional materials.

Sustainability is an increasingly important concern across industries, and FRP fittings align well with this trend. Made from recyclable materials, FRP has a lower carbon footprint compared to conventional options. This aligns with the growing push for eco-friendly solutions, helping organizations meet their sustainability goals while maintaining operational efficiency.

As industries continue to evolve, so too do the technologies that support them. The adoption of FRP fittings is a clear demonstration of the shift towards modern materials that meet the demands of a changing world. As awareness grows regarding the benefits of FRP fittings—ranging from cost-effectiveness to environmental considerations—more industries are likely to incorporate them into their systems.

In conclusion, FRP fittings represent a significant advancement in piping and fitting solutions, addressing many challenges posed by traditional materials. With their lightweight, corrosion-resistant, and customizable nature, they are paving the way for more efficient and sustainable practices in various sectors. As industries embrace these modern solutions, FRP fittings will undoubtedly play a crucial role in shaping the future of engineering and construction.