-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

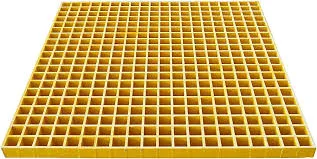

frp piping system

Understanding FRP Piping Systems

Fiber Reinforced Plastic (FRP) piping systems have gained significant attention in various industries due to their superior characteristics compared to traditional materials such as metal and concrete. Composed primarily of a polymer matrix reinforced with fibers—usually glass, carbon, or aramid—FRP pipes offer an innovative solution for numerous piping applications.

Understanding FRP Piping Systems

Another important benefit of FRP piping systems is their lightweight nature. FRP pipes are significantly lighter than traditional steel or concrete pipes, making them easier and cheaper to transport and install. This characteristic is especially advantageous in construction sites where labor costs and equipment usage are paramount considerations. The reduced weight of FRP also contributes to lower structural support requirements, allowing for more flexible design options.

frp piping system

Additionally, FRP pipes exhibit excellent thermal and electrical insulation properties. This is particularly valuable in industries where thermal stability is crucial, such as in the oil and gas sector. The insulating properties can help in maintaining the desired temperature of the transported fluids and can prevent energy loss in heating or cooling applications. Moreover, the non-conductive nature of FRP minimizes risks associated with electrical conductivity, making FRP piping an ideal choice in various industrial settings.

Durability is another notable feature of FRP piping systems. These pipes are designed to withstand extreme environmental conditions, including high pressures and temperatures. Their structural integrity and longevity result in a lower life-cycle cost, making them a more economical option over the long term compared to traditional piping materials.

In terms of installation, FRP piping systems offer enhanced flexibility. They can be molded into a variety of shapes and configurations, which allows for easy integration into existing piping networks without the need for extensive modifications. This adaptability is crucial in industries where space is limited or where specific piping layouts are necessary for optimal system performance.

In conclusion, FRP piping systems present a multitude of advantages that make them an appealing choice for modern piping solutions. With their corrosion resistance, lightweight nature, thermal and electrical insulation properties, durability, and installation flexibility, FRP pipes are poised to play an increasingly important role in diverse industrial applications. As technology continues to evolve, the use of FRP materials is likely to expand, offering innovative solutions to meet the demands of various sectors while ensuring sustainability and efficiency.