-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

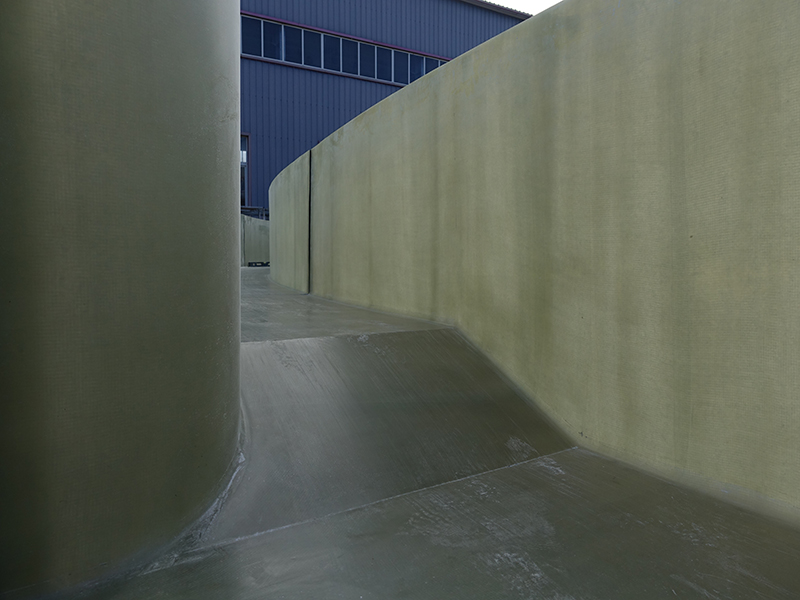

frp shell

Understanding FRP Shells A Modern Approach to Structural Engineering

Fiber-Reinforced Polymer (FRP) shells represent a significant advancement in the field of structural engineering. As an innovative composite material, FRP is composed of a polymer matrix reinforced with high-strength fibers such as glass, carbon, or aramid. This combination provides superior mechanical properties, making FRP shells an attractive option for various applications, ranging from civil engineering structures to aerospace components.

.

In addition to being lightweight, FRP materials exhibit excellent resistance to corrosion and environmental degradation. Unlike traditional metal structures that succumb to rust and wear over time, FRP shells remain stable and durable under harsh conditions, including exposure to moisture, chemicals, and UV radiation. This characteristic not only extends the lifespan of the structures but also reduces maintenance costs, making them a cost-effective solution in the long run.

frp shell

The versatility of FRP shells extends to their design flexibility. The composite materials can be molded into complex shapes that would be difficult to achieve with conventional materials. This adaptability allows for more creative architectural designs, enabling engineers and architects to push the boundaries of their imagination while ensuring structural integrity. Additionally, the manufacturing processes for FRP shells can be tailored to produce a variety of geometries, further enhancing their applicability in different projects.

Moreover, the deployment of FRP shells aligns with contemporary sustainability goals. As the construction industry increasingly focuses on reducing its carbon footprint, the use of lightweight and durable materials like FRP contributes to energy efficiency during both production and operation phases. The reduced need for heavy machinery during installation and lower transportation costs due to the material's lightweight nature synergistically minimize environmental impact.

However, it is essential to consider some challenges associated with the use of FRP shells. Their initial cost can be higher than traditional materials, which may deter some project developers. Additionally, while the material has been extensively tested in many applications, ongoing research is necessary to fully understand the long-term performance of FRP shells in various environmental conditions and loads.

In conclusion, FRP shells represent a promising direction in structural engineering, combining lightweight design, corrosion resistance, and flexibility. As technological advancements continue to evolve, the integration of FRP shells in construction practices is expected to become more prevalent, paving the way for innovative, sustainable, and resilient structures that meet the demands of the modern world. Embracing such materials not only enhances the engineering capabilities but also aligns with the global shift towards more sustainable construction practices.