-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

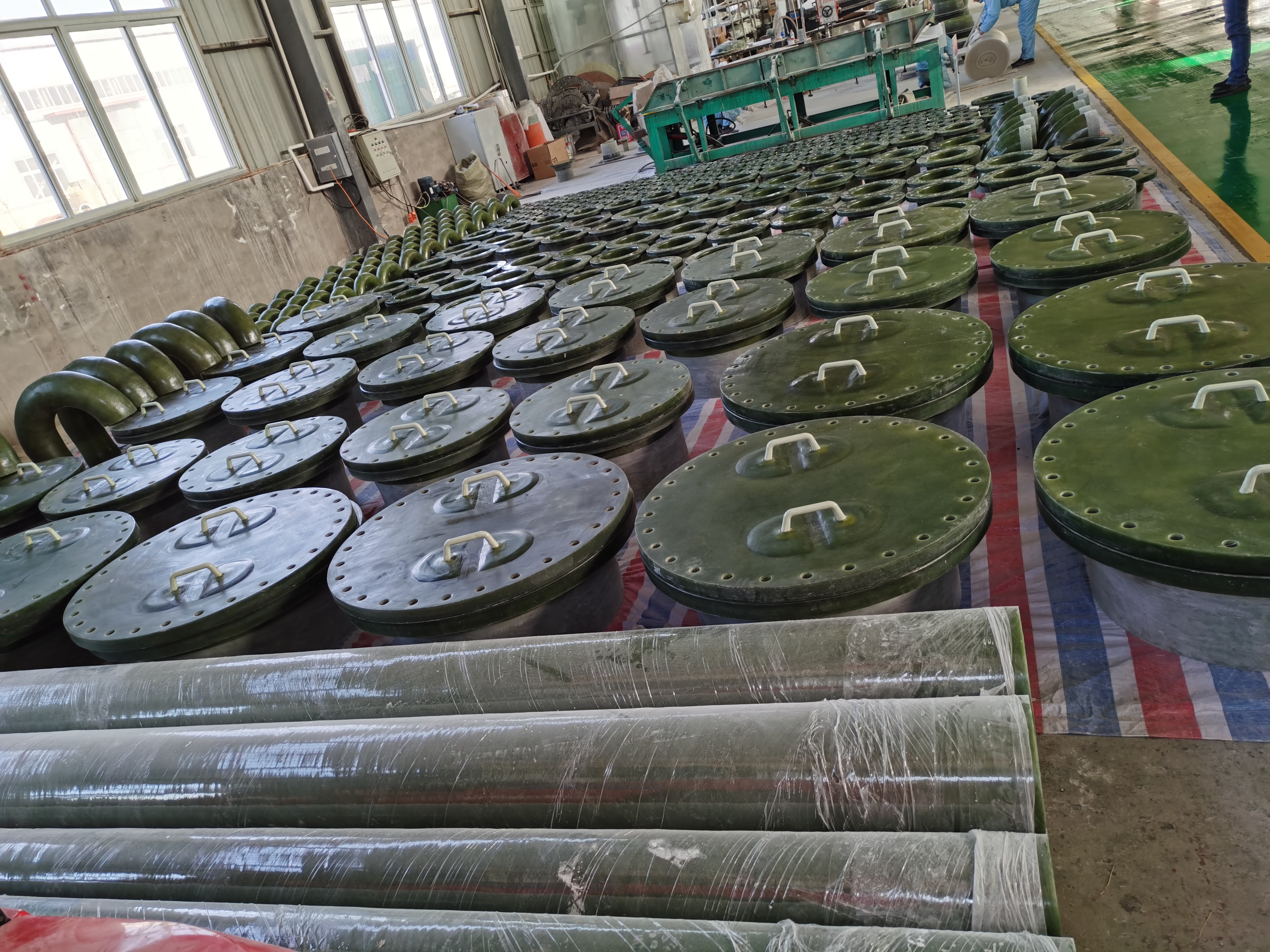

Innovative FRP Transition Solutions for Enhanced Performance

Understanding FRP Transition A Comprehensive Overview

Fiber Reinforced Polymer (FRP) materials have gained significant attention in various industries, especially in construction, aerospace, and automotive fields. Transitioning to FRP technologies involves not only integrating these materials into existing processes but also adapting to new methodologies that can enhance performance and sustainability. This article explores the concept of FRP transition, its benefits, challenges, and future prospects.

Understanding FRP Transition A Comprehensive Overview

One of the primary benefits of transitioning to FRP is increased durability. Unlike steel, which can corrode over time, FRP materials are resistant to a variety of environmental factors, including moisture and chemicals. This resilience results in longer service life and lower maintenance costs. In the construction industry, FRP is often used in bridges and buildings where traditional materials may suffer from degradation due to environmental exposure.

frp transition

However, this transition is not without its challenges. One of the most critical hurdles facing the adoption of FRP technologies is the initial cost. While FRP can offer long-term savings, the upfront investment in terms of material and manufacturing processes can be prohibitive. Additionally, the integration of FRP into conventional construction practices requires substantial training and education for engineers and construction workers to understand the unique properties and handling requirements of these materials.

Another challenge is the need for standardized codes and practices. The construction and manufacturing industries are heavily regulated, and the lack of widespread standards for FRP can create obstacles for adoption. Stakeholders must collaborate to develop guidelines that ensure the safe and effective use of FRP in various applications.

Despite these challenges, the future of FRP transition looks promising. Ongoing research and development in materials science are likely to lead to advancements that reduce costs and improve the performance of FRP materials. Furthermore, as industries worldwide increasingly prioritize sustainability, the adoption of FRP can play a pivotal role in achieving environmental goals. The ability to produce lighter, more durable structures aligns with global initiatives aimed at reducing the carbon footprint of various industries.

In conclusion, the transition to Fiber Reinforced Polymer materials represents a significant shift in how industries approach design, construction, and manufacturing. While challenges such as cost and regulatory standards remain, the long-term benefits of durability, reduced weight, and sustainability present a compelling case for moving towards FRP. As technology continues to evolve and improve, the widespread adoption of FRP could redefine material choices across multiple sectors, paving the way for a more innovative and sustainable future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025