-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp absorber

Frp Absorber An Innovative Solution for Energy Absorption

Fiber Reinforced Polymer (FRP) absorbers are becoming increasingly significant in the realm of engineering and materials science, particularly in the context of advanced structural applications. These innovative materials combine high strength, low weight, and excellent durability, making them ideal for a variety of energy absorption applications. The development and utilization of FRP absorbers is a promising avenue for enhancing the safety and efficiency of structures subjected to dynamic loads.

Frp Absorber An Innovative Solution for Energy Absorption

FRP absorbers are manufactured using various fibers, including glass, carbon, and aramid, embedded in a polymer matrix. The choice of fiber and matrix affects the overall performance of the absorber. For instance, carbon fibers are known for their high strength-to-weight ratio, making them ideal for applications requiring maximum energy absorption with minimal bulk. Similarly, glass fibers offer a cost-effective alternative while still providing adequate performance characteristics for most applications.

frp absorber

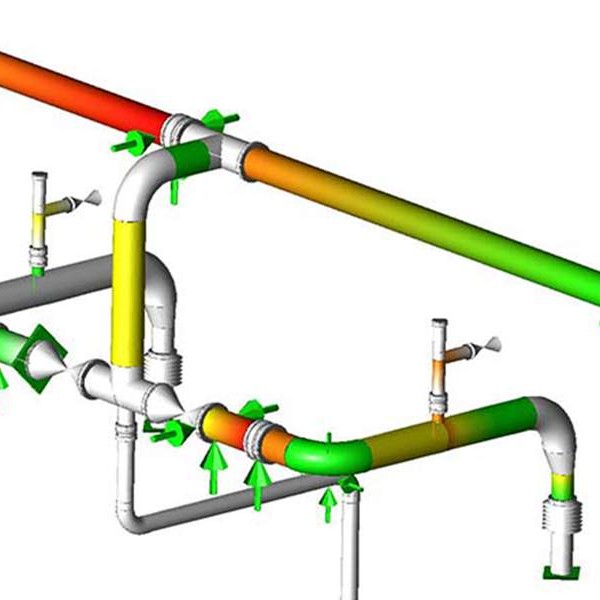

The design of FRP absorbers typically involves optimizing the configuration and layering of the fibers to enhance their energy absorption capabilities. Recent advancements in computational modeling allow engineers to simulate the behavior of these materials under various loading conditions, leading to better-informed design choices. By tailoring the architecture of the FRP absorbers, it is possible to achieve desired energy absorption characteristics, ensuring that the structure can effectively handle the expected dynamic loads.

Another important aspect of FRP absorbers is their environmental resilience. Unlike traditional materials, FRP composites exhibit excellent corrosion resistance and longevity, making them suitable for exposure to harsh conditions. This property not only extends the lifespan of the structures but also reduces maintenance costs, offering a more sustainable option in the long run.

In addition to structural applications, FRP absorbers are also finding their way into automotive and aerospace industries. Here, they are utilized in components designed to absorb impact energy during collisions, thereby enhancing passenger safety. The lightweight nature of FRP materials contributes directly to fuel efficiency in vehicles and aircraft, making them a dual benefit solution.

In conclusion, FRP absorbers represent a significant advancement in the field of energy absorption materials. Their unique combination of strength, durability, and lightweight characteristics makes them highly effective for a wide range of applications, from civil engineering to transportation. As research continues and technology develops, the role of FRP absorbers in various industries is expected to expand, leading to safer and more efficient structural designs. The future of energy absorption looks promising with the continued integration of these advanced materials into our infrastructure.