-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

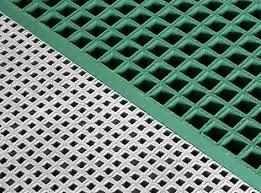

frp absorber

The Importance of FRP Absorbers in Modern Engineering

Fiber Reinforced Polymer (FRP) absorbers have emerged as a significant innovation in various engineering fields, particularly for noise and vibration control. As urbanization increases and industries grow, the need for effective sound absorption and vibration damping solutions becomes more critical. FRP absorbers offer a lightweight, durable, and efficient alternative to traditional materials, making them invaluable in modern engineering applications.

What are FRP Absorbers?

FRP absorbers are composite materials consisting of a polymer matrix reinforced with fibers, typically glass or carbon. The combination of these materials results in products that exhibit an impressive balance of strength, stiffness, and lightness. One of the key properties of FRP is its ability to absorb and dissipate energy, making it particularly effective in mitigating sound and vibrations in various environments.

Applications of FRP Absorbers

One of the most notable applications of FRP absorbers is in the field of construction and building acoustics. In urban environments, where noise pollution is a significant concern, FRP absorbers can be integrated into walls, ceilings, and facades to enhance acoustic performance. By effectively trapping and reducing sound waves, these materials contribute to creating quieter indoor spaces, leading to improved comfort and productivity for occupants.

Moreover, FRP absorbers are extensively used in the automotive and aerospace industries. Vehicles and aircraft are subjected to numerous vibrations during operation, which can lead to material fatigue and reduce overall performance. By integrating FRP absorbers into vehicle structures, manufacturers can enhance the durability and stability of their products while simultaneously improving ride quality for users. This not only augments the consumer experience but also reduces the need for maintenance and repairs, leading to cost savings in the long run.

frp absorber

In the realm of industrial machinery, FRP absorbers play a pivotal role in reducing noise and mechanical vibrations. Heavy machinery often generates significant sound pollution, which can have harmful effects on workers’ health and safety. The incorporation of FRP absorbers into these systems helps to create a safer working environment by lowering noise levels and minimizing vibration-related wear and tear on equipment. Consequently, this results in increased operational efficiency and longevity of machinery.

Benefits of Using FRP Absorbers

The advantages of FRP absorbers extend beyond their acoustic properties. One of the most significant benefits is their lightweight nature compared to conventional materials like concrete or metal. This characteristic not only facilitates easier handling and installation but also contributes to overall energy savings during transportation and construction.

Additionally, FRP materials exhibit high resistance to corrosion and environmental degradation. This makes them suitable for use in harsh environments where traditional materials might falter, such as coastal regions or industrial settings with chemical exposure. By preventing deterioration, FRP absorbers ensure longevity and reduce lifecycle costs, making them a cost-effective solution in the long term.

Conclusion

In summary, FRP absorbers represent a significant advancement in engineering materials, providing versatile solutions for a variety of applications related to sound and vibration management. Their lightweight, durable, and resilient nature makes them ideal for modern challenges in urban construction, automotive design, aerospace engineering, and industrial machinery. As technology advances and the demand for effective noise and vibration control continues to grow, the role of FRP absorbers in enhancing quality of life, safety, and productivity will only become more prominent. As industries increasingly prioritize sustainability and efficiency, FRP absorbers stand out as a forward-thinking solution, combining performance with environmental considerations to meet the needs of the future.