-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

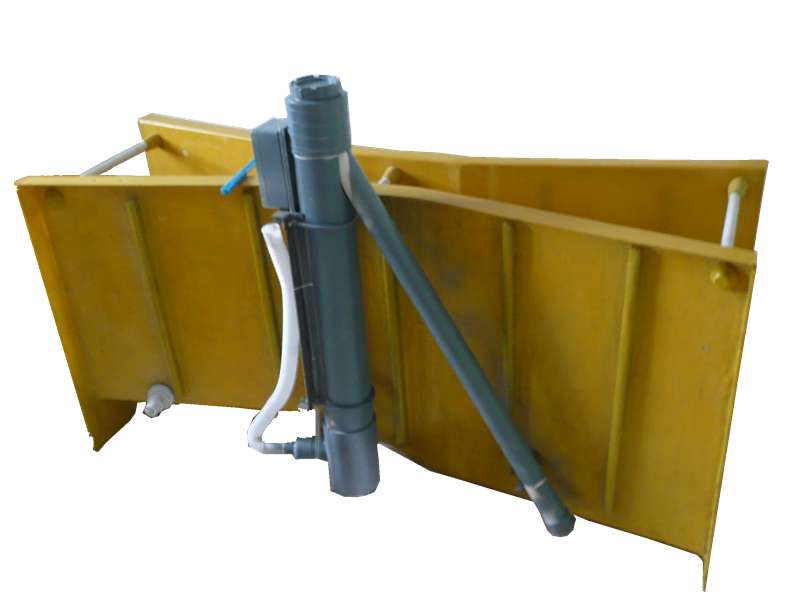

frp absorber

Understanding FRP Absorbers Applications and Benefits

Fiber-Reinforced Polymer (FRP) absorbers have emerged as a pivotal component in the modern landscape of engineering and environmental management. Renowned for their superior strength-to-weight ratio and excellent corrosion resistance, these materials provide innovative solutions in various fields, including construction, transportation, and waste management. This article delves into the significance, applications, and advantages of FRP absorbers.

What Are FRP Absorbers?

FRP absorbers are composite materials composed of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This combination lends FRP attributes that are not only lightweight and durable but also able to absorb sound and vibrations effectively. The unique properties of FRP make it an ideal choice for applications requiring resilience against environmental factors and mechanical stress.

Applications of FRP Absorbers

FRP absorbers can be found in multiple domains

1. Construction In civil engineering, FRP materials are used to create noise barriers, which serve to mitigate sound pollution in urban areas. These barriers are strategically placed alongside highways and railway tracks to absorb noise, providing a quieter environment for residential areas.

2. Transportation The automotive and aerospace industries leverage FRP absorbers to improve the acoustic comfort of vehicles. By incorporating these materials into the design of cars and aircraft, manufacturers can minimize noise from engines and external environments, enhancing the overall user experience.

3. Environmental Management In waste treatment facilities, FRP absorbers are employed to manage noise generated from operations. Their ability to absorb sound waves effectively helps in complying with environmental regulations and improving the quality of life for nearby communities.

4. Industrial Applications FRP absorbers are also utilized in industrial settings where machinery operates at high decibel levels. The placement of FRP materials around equipment can significantly reduce noise, ensuring a safer and more comfortable working environment.

frp absorber

Advantages of FRP Absorbers

The utilization of FRP absorbers presents numerous benefits that underline their growing popularity

1. Lightweight One of the standout characteristics of FRP is its lightweight nature. This feature simplifies transportation and installation, translating into cost savings in labor and logistics.

2. Durability FRP materials boast excellent resistance to corrosion, fatigue, and wear. Unlike traditional materials, FRP is not subject to degradation from environmental factors like moisture, making it a long-lasting solution.

3. Design Flexibility FRP allows for greater design freedom. Engineers can mold these materials into complex shapes and sizes, ensuring that they fit seamlessly into a variety of applications without compromising performance.

4. Sustainability With increasing emphasis on sustainable practices, FRP absorbers can contribute to greener solutions. Their longevity reduces the need for frequent replacements, minimizing waste and resource consumption over time.

5. Cost-Effectiveness Although the initial investment in FRP materials might be higher than traditional options, the long-term savings due to their durability and low maintenance needs can offset the initial costs, making them a financially sound choice.

Conclusion

FRP absorbers represent a significant advancement in material technology, offering effective solutions for noise reduction and vibration control across a wide range of applications. Their unique combination of lightweight construction, durability, and design flexibility positions them as a preferred choice for engineers and designers alike.

As industries increasingly seek sustainable and innovative solutions, the role of FRP absorbers will continue to grow, paving the way for enhanced acoustic environments and improved quality of life in urban and industrial settings. The future of noise and vibration management appears promising, thanks to the capabilities of Fiber-Reinforced Polymer absorbers.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025