-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 15, 2025 10:22

Back to list

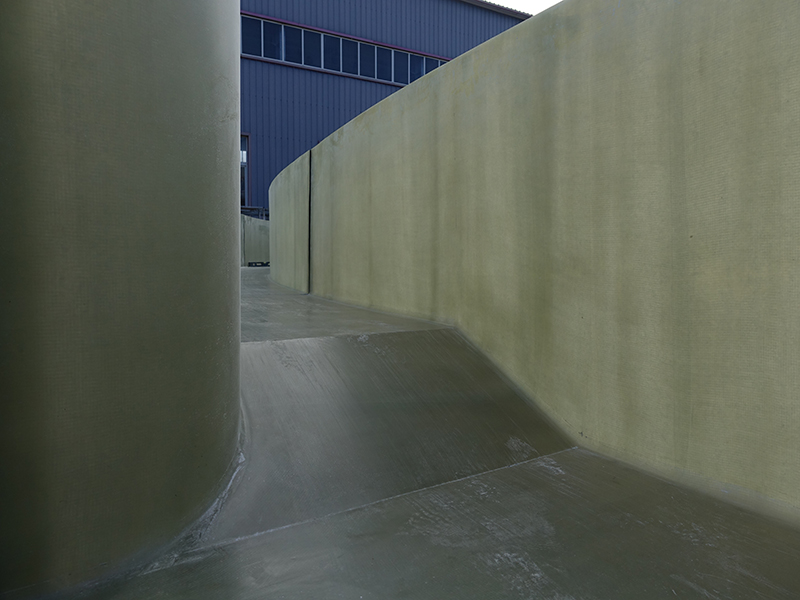

frp absorber

When considering the optimal materials for enhancing industrial efficiency and ensuring environmental protection, the FRP absorber emerges as a formidable solution. An acronym for Fiberglass Reinforced Plastic, FRP combines the lightweight strength of fiberglass with the versatility of plastic, offering remarkable advantages in various industrial applications. Over the years, my experience collaborating with top-tier industrial facilities has reinforced the essential role of FRP absorbers in achieving sustainable, high-performance systems.

Trustworthiness is paramount when discussing materials for industrial applications, and the credibility of FRP absorbers is backed by comprehensively documented case studies and academic research. Over decades, successful deployments in adverse environments have underscored their reliability. Testimonials from industry leaders resonate with the assurance that FRP absorbers meet and exceed rigorous industrial standards, bolstering confidence in their application across various sectors. In terms of performance, facilities utilizing FRP absorbers often report an uptick in operational efficiency. Case after case reveals decreased downtime and improved safety records due largely to the mechanical resilience and environmental compatibility of FRP. Furthermore, noise reduction properties are an added advantage in enhancing workplace environments, contributing to better compliance with occupational health standards. In a rapidly evolving industrial landscape, selecting the appropriate materials for environmental management systems becomes increasingly critical. The adoption of FRP absorbers represents not just a nod to innovation, but a commitment to sustainability, efficiency, and economic prudence. As industries advance towards greener and more efficient methods, FRP absorbers will undoubtedly continue to be at the forefront of this transformation. My extensive engagement with FRP technology reassures me of its indispensable role in shaping the future of industrial applications. For plants and factories aiming to optimize their systems, lower operational costs, and adhere to environmental guidelines, FRP absorbers present a prime solution that combines cutting-edge technology with proven reliability.

Trustworthiness is paramount when discussing materials for industrial applications, and the credibility of FRP absorbers is backed by comprehensively documented case studies and academic research. Over decades, successful deployments in adverse environments have underscored their reliability. Testimonials from industry leaders resonate with the assurance that FRP absorbers meet and exceed rigorous industrial standards, bolstering confidence in their application across various sectors. In terms of performance, facilities utilizing FRP absorbers often report an uptick in operational efficiency. Case after case reveals decreased downtime and improved safety records due largely to the mechanical resilience and environmental compatibility of FRP. Furthermore, noise reduction properties are an added advantage in enhancing workplace environments, contributing to better compliance with occupational health standards. In a rapidly evolving industrial landscape, selecting the appropriate materials for environmental management systems becomes increasingly critical. The adoption of FRP absorbers represents not just a nod to innovation, but a commitment to sustainability, efficiency, and economic prudence. As industries advance towards greener and more efficient methods, FRP absorbers will undoubtedly continue to be at the forefront of this transformation. My extensive engagement with FRP technology reassures me of its indispensable role in shaping the future of industrial applications. For plants and factories aiming to optimize their systems, lower operational costs, and adhere to environmental guidelines, FRP absorbers present a prime solution that combines cutting-edge technology with proven reliability.

Next:

Related Products