-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 17, 2025 04:26

Back to list

Ship Pipings and Fittings

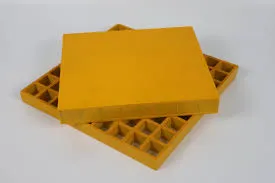

FRP (Fiberglass Reinforced Plastic) blind flanges are an integral component within the realm of modern industrial applications. These components offer a combination of lightweight yet robust characteristics that make them ideal for use across various industries such as chemical processing, water treatment, and oil and gas.

Authoritative voices in the industry often highlight the adaptability of FRP blind flanges. They are available in a range of configurations that align with standard pipe sizes and pressure ratings. This versatility allows them to be incorporated seamlessly into both new installations and retrofitting projects, offering an economic and efficient solution to pipeline termination. A critical yet often overlooked aspect of FRP blind flange utilization is the associated trustworthiness of the suppliers. Partnering with reputable manufacturers who have a proven track record and positive customer testimonials can significantly influence the success of an installation. Reputable suppliers possess comprehensive technical know-how, ensuring their products are consistently of high quality and delivered on time. Furthermore, the emphasis on sustainability in recent years has pushed the development of FRP blind flanges further into the spotlight. The manufacturing process of FRP materials is environmentally friendly, producing significantly less waste than traditional metalworking methods. Additionally, the longevity and durability of FRP products minimize the need for frequent replacements, contributing to sustainable practices by reducing material consumption over time. In practical application, the installation of FRP blind flanges is straightforward. They can be joined to pipelines using standard bolting methods, and their lightweight nature reduces the need for heavy lifting equipment, facilitating more efficient and safer installation procedures. This ease of installation, combined with low maintenance requirements, translates into significant cost savings over the lifecycle of a project. In conclusion, FRP blind flanges offer a plethora of advantages that cater to the stringent requirements of modern pipeline systems. Their corrosion resistance, customizable nature, and ease of installation make them an advantageous choice for industries aiming to maintain robust and reliable systems. By choosing FRP blind flanges from reputable manufacturers, industries not only invest in durable infrastructure but also align with sustainable and cost-effective practices. As industry standards continue to evolve, FRP will undoubtedly remain a material of choice for forward-thinking engineers and project managers who prioritize quality and longevity in their specifications.

Authoritative voices in the industry often highlight the adaptability of FRP blind flanges. They are available in a range of configurations that align with standard pipe sizes and pressure ratings. This versatility allows them to be incorporated seamlessly into both new installations and retrofitting projects, offering an economic and efficient solution to pipeline termination. A critical yet often overlooked aspect of FRP blind flange utilization is the associated trustworthiness of the suppliers. Partnering with reputable manufacturers who have a proven track record and positive customer testimonials can significantly influence the success of an installation. Reputable suppliers possess comprehensive technical know-how, ensuring their products are consistently of high quality and delivered on time. Furthermore, the emphasis on sustainability in recent years has pushed the development of FRP blind flanges further into the spotlight. The manufacturing process of FRP materials is environmentally friendly, producing significantly less waste than traditional metalworking methods. Additionally, the longevity and durability of FRP products minimize the need for frequent replacements, contributing to sustainable practices by reducing material consumption over time. In practical application, the installation of FRP blind flanges is straightforward. They can be joined to pipelines using standard bolting methods, and their lightweight nature reduces the need for heavy lifting equipment, facilitating more efficient and safer installation procedures. This ease of installation, combined with low maintenance requirements, translates into significant cost savings over the lifecycle of a project. In conclusion, FRP blind flanges offer a plethora of advantages that cater to the stringent requirements of modern pipeline systems. Their corrosion resistance, customizable nature, and ease of installation make them an advantageous choice for industries aiming to maintain robust and reliable systems. By choosing FRP blind flanges from reputable manufacturers, industries not only invest in durable infrastructure but also align with sustainable and cost-effective practices. As industry standards continue to evolve, FRP will undoubtedly remain a material of choice for forward-thinking engineers and project managers who prioritize quality and longevity in their specifications.

Next:

Related Products