-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 06, 2025 04:37

Back to list

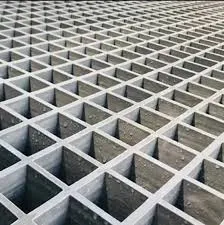

frp blind flange

Fiber Reinforced Plastic (FRP) blind flanges have become an essential component in various industrial applications due to their unique properties and advantages over traditional metal counterparts. As an SEO expert with in-depth understanding of industrial equipment, it's clear that providing reliable, expert content on FRP blind flanges can significantly enhance online visibility and authority.

From a manufacturing perspective, FRP blind flanges provide an additional advantage in terms of customization. Manufacturers can tailor the fiber orientation and composition to meet specific mechanical requirements, ensuring that the end product aligns precisely with the intended application. This level of customization is challenging to achieve with traditional materials, positioning FRP as a leading solution for bespoke industrial needs. Expert installation is crucial to maximizing the benefits of FRP blind flanges. While the handling might be straightforward, ensuring proper alignment and secure sealing can significantly impact the performance of the flange in service. Professionals equipped with the right tools and knowledge can install FRP blind flanges efficiently, thereby enhancing the reliability of the entire system. The growing trend towards sustainable and green practices in industrial operations further amplifies the appeal of FRP blind flanges. The production processes for these materials often require less energy compared to metals, leading to a smaller carbon footprint. Additionally, the long service life and minimal maintenance needs of FRP contribute to more sustainable operations over time. Research and development in the field of composite materials continue to push the boundaries of FRP capabilities. Ongoing innovations promise even greater strength-to-weight ratios, enhanced thermal properties, and broader chemical resistance. These advances ensure that FRP blind flanges remain at the forefront of industrial material solutions well into the future. In summary, FRP blind flanges offer substantial benefits, including superior chemical resistance, reduced weight, and customization opportunities. Their role in promoting sustainability due to reduced maintenance and energy-efficient properties adds to their appeal. By highlighting these advantages, industries can make informed decisions that enhance operational efficiency and reliability, thereby positioning FRP blind flanges as a cornerstone in modern industrial applications.

From a manufacturing perspective, FRP blind flanges provide an additional advantage in terms of customization. Manufacturers can tailor the fiber orientation and composition to meet specific mechanical requirements, ensuring that the end product aligns precisely with the intended application. This level of customization is challenging to achieve with traditional materials, positioning FRP as a leading solution for bespoke industrial needs. Expert installation is crucial to maximizing the benefits of FRP blind flanges. While the handling might be straightforward, ensuring proper alignment and secure sealing can significantly impact the performance of the flange in service. Professionals equipped with the right tools and knowledge can install FRP blind flanges efficiently, thereby enhancing the reliability of the entire system. The growing trend towards sustainable and green practices in industrial operations further amplifies the appeal of FRP blind flanges. The production processes for these materials often require less energy compared to metals, leading to a smaller carbon footprint. Additionally, the long service life and minimal maintenance needs of FRP contribute to more sustainable operations over time. Research and development in the field of composite materials continue to push the boundaries of FRP capabilities. Ongoing innovations promise even greater strength-to-weight ratios, enhanced thermal properties, and broader chemical resistance. These advances ensure that FRP blind flanges remain at the forefront of industrial material solutions well into the future. In summary, FRP blind flanges offer substantial benefits, including superior chemical resistance, reduced weight, and customization opportunities. Their role in promoting sustainability due to reduced maintenance and energy-efficient properties adds to their appeal. By highlighting these advantages, industries can make informed decisions that enhance operational efficiency and reliability, thereby positioning FRP blind flanges as a cornerstone in modern industrial applications.

Next:

Related Products