-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

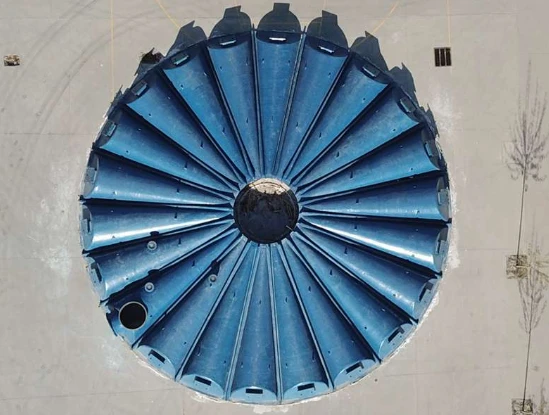

frp car

Exploring the World of FRP Cars Innovation Meets Performance

In the ever-evolving landscape of automotive engineering, the integration of advanced materials has sparked significant innovation, leading to the rise of FRP cars—vehicles crafted from Fiberglass Reinforced Plastic (FRP). This revolutionary material, known for its impressive strength-to-weight ratio, has transformed the way cars are designed and manufactured, pushing the boundaries of performance, safety, and aesthetic appeal.

What is FRP?

Fiberglass Reinforced Plastic is a composite material that consists of a polymer matrix reinforced by glass fibers. This combination yields a lightweight yet extremely strong material ideal for a wide range of applications, including the automotive industry. The unique properties of FRP allow manufacturers to create cars that are not only lighter but also more fuel-efficient, offering an eco-friendlier alternative to traditional metal-bodied vehicles.

Advantages of FRP Cars

1. Weight Reduction One of the most significant advantages of using FRP in car manufacturing is the substantial weight reduction. Cars made from FRP can be up to 30-50% lighter than their metal counterparts. This reduction in weight translates to improved acceleration, handling, and fuel efficiency, making FRP cars an attractive option for both manufacturers and consumers.

2. Corrosion Resistance Unlike steel or aluminum, FRP does not corrode. This characteristic makes FRP cars highly durable, requiring less maintenance over the vehicle's lifespan. In regions prone to humidity or where road salt is commonly used, the corrosion-resistant nature of FRP provides a significant benefit, enhancing the car's longevity.

3. Design Flexibility The molding process for FRP allows for greater design flexibility compared to traditional materials. Engineers can create intricate shapes and styles that would be difficult, if not impossible, to achieve with metal. This capability has led to the design of modern, aerodynamic vehicles that are as visually striking as they are efficient.

4. Thermal Insulation Fiberglass offers excellent thermal insulation properties, helping to maintain comfortable cabin temperatures and improving fuel efficiency. This insulation feature can be particularly advantageous in electric vehicles, where temperature management is crucial for battery performance.

frp car

Future of FRP in the Automotive Industry

The automotive industry is shifting towards sustainability, and FRP plays a crucial role in this transition. Many manufacturers are increasingly looking to composite materials to reduce their carbon footprint and improve vehicle efficiency. The growing trend of electric and hybrid vehicles has further propelled the demand for lightweight materials like FRP, as reducing weight is essential for optimizing battery life and range.

Additionally, advancements in production methods, such as automated fiber placement and additive manufacturing, are making it easier and more cost-effective to produce FRP components. As technology continues to evolve, the potential for FRP in automotive applications is boundless.

Examples of FRP Cars

While several manufacturers have experimented with FRP components, some notable examples of FRP cars include the iconic Chevrolet Corvette and the Lamborghini Gallardo. Both models utilize FRP in various body parts, contributing to their performance and aesthetics. The Corvette, known for its speed and agility, has benefited from the lightweight nature of FRP, allowing it to achieve higher speeds with greater control.

Challenges Ahead

Despite its numerous advantages, the adoption of FRP in mainstream automotive manufacturing is not without challenges. One significant hurdle is the perception of FRP as a lesser material compared to metals. Some consumers remain hesitant about the durability and safety of vehicles made from composites. Furthermore, recycling FRP poses a significant challenge, as many traditional recycling processes are not equipped to handle composite materials effectively.

Conclusion

As the automotive industry continues to embrace innovation, FRP cars represent a significant step toward a more sustainable and efficient future. With their lightweight design, corrosion resistance, and aesthetic versatility, FRP vehicles are poised to reshape our roads and driving experiences. As technology advances and production methods improve, we can expect to see an increasing number of FRP cars on the market, setting new standards for performance, safety, and environmental responsibility.