-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

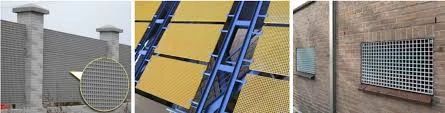

frp car

The Rise of FRP Cars A New Era in Automotive Engineering

In the realm of automotive engineering, the conversation has increasingly shifted towards the use of advanced materials in vehicle manufacturing. Among these, Fiber Reinforced Polymer (FRP) stands out as a game-changer, offering a myriad of benefits that are transforming the industry. As we delve into the world of FRP cars, it becomes evident that they are not just vehicles; they symbolize a new era of innovation and sustainability in the automotive sector.

FRP is a composite material made from a polymer matrix reinforced with fibers. Commonly used fibers include glass, carbon, and aramid, each providing unique strength-to-weight ratios and durability. This combination allows for the creation of lightweight structures without sacrificing strength, making FRP an ideal choice for automotive applications. The significance of weight reduction in cars cannot be overstated; lighter vehicles lead to improved fuel efficiency, better acceleration, and enhanced handling. As environmental concerns continue to escalate, manufacturers are pressed to develop vehicles that consume less fuel and produce fewer emissions. Here, FRP plays a pivotal role.

.

Companies such as Ferrari and Lamborghini have been at the forefront of incorporating FRP into their supercar designs. These manufacturers leverage the material's properties to create lightweight chassis and body components, pushing the limits of speed and performance. The introduction of carbon-fiber-reinforced polymer has enabled these brands to produce cars that are not only faster but also safer, with stronger passenger cells designed to withstand high-impact collisions.

frp car

Moreover, the integration of FRP into electric vehicles (EVs) has fueled innovation. The demand for lighter and more energy-efficient cars aligns perfectly with the properties of FRP. By employing these materials, automakers can enhance the range and performance of EVs while also addressing range anxiety—one of the significant barriers to widespread EV adoption. Companies like Tesla are already exploring the possibilities that FRP offers, positioning themselves as leaders in sustainable automotive solutions.

However, the journey of FRP in automotive manufacturing is not without challenges. While the benefits are plentiful, the cost of production remains a significant hurdle. The manufacturing processes for FRP can be expensive, particularly when it comes to carbon fiber. As a result, many manufacturers are still weighing the cost-benefit ratio when considering the full-scale deployment of these materials. Research and development into more cost-effective manufacturing methods hold the key to unlocking the full potential of FRP in the automotive industry.

Another critical aspect to consider is the end-of-life management of FRP components. Unlike metals, which can be easily recycled, recycling FRP is still a developing field. As environmental regulations tighten and consumer awareness grows, the automotive industry will need to address the sustainability of materials beyond their use in vehicles. Innovative recycling techniques and a focus on circular economy principles will be crucial in making FRP a truly sustainable choice moving forward.

In conclusion, FRP cars signify a remarkable advancement in automotive engineering, offering a blend of performance, efficiency, and design that is reshaping the future of mobility. While there are challenges to overcome, the potential of FRP is undeniable, positioning it as a vital component in the evolution of safe, sustainable, and high-performance vehicles. As the industry continues to innovate, FRP will undoubtedly play a crucial role in driving the automotive world towards a more sustainable and dynamic future. With the right investments in research, development, and recycling technologies, the dream of a greener automotive industry may soon become a reality.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025