-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

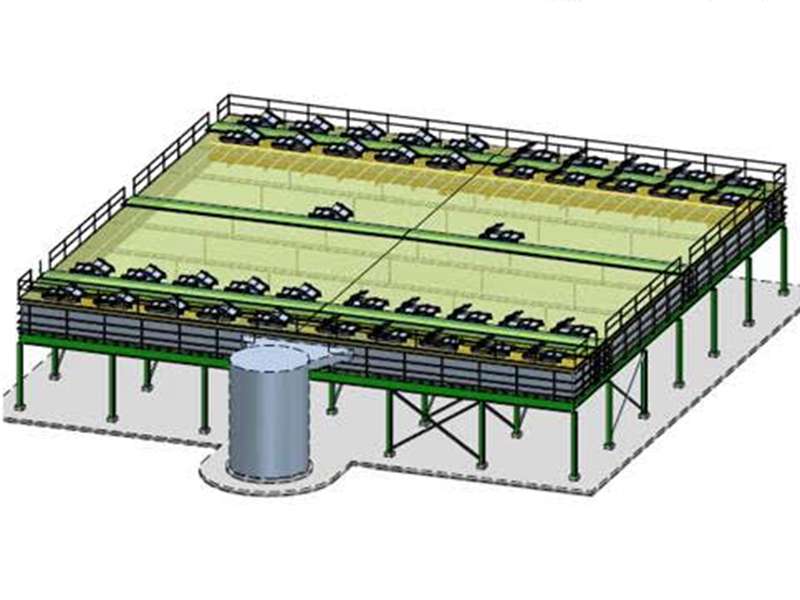

frp car body

Exploring the FRP Car Body A Step Forward in Automotive Engineering

In the ever-evolving world of automotive engineering, the development of lightweight and durable materials has become paramount for enhancing vehicle performance, fuel efficiency, and safety. One innovative material gaining significant attention in recent years is Fiber Reinforced Plastic (FRP). The application of FRP in car bodies represents a transformative step forward in vehicle design and production, offering numerous benefits over traditional materials such as steel or aluminum.

What is FRP?

FRP, or Fiber Reinforced Plastic, is a composite material made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This combination results in a material that exhibits remarkable strength-to-weight ratios, high corrosion resistance, and improved durability. The versatility of FRP allows engineers to tailor its properties for specific applications, making it an ideal choice for automotive manufacturers seeking to enhance their vehicles’ performance.

Advantages of FRP Car Bodies

1. Weight Reduction One of the most significant advantages of using FRP in car bodies is the substantial reduction in weight. Traditional automotive materials like steel are dense and contribute significantly to the overall weight of the vehicle. In contrast, FRP is much lighter, enabling manufacturers to produce vehicles that are not only easier to handle but also more energy-efficient. Lighter cars require less power to achieve the same performance levels, resulting in improved fuel economy and reduced greenhouse gas emissions.

Exploring the FRP Car Body A Step Forward in Automotive Engineering

3. Corrosion Resistance One of the most significant drawbacks of metal car bodies is their susceptibility to rust and corrosion, which can compromise a vehicle’s integrity over time. FRP is inherently resistant to corrosion, which means vehicles with FRP bodies can have a longer lifespan and reduced maintenance costs. This quality is particularly advantageous in regions with harsh weather conditions or where roads are treated with corrosive chemicals.

frp car body

4. Design Flexibility FRP materials can be molded into complex shapes far more easily than metals, allowing automotive designers greater freedom to innovate. This flexibility can lead to more aerodynamic designs, enhancing fuel efficiency and aesthetic appeal. Manufacturers can create smoother lines and unique body shapes that were previously difficult to achieve with traditional materials.

5. Environmental Impact As the automotive industry pivots toward sustainability, using FRP can contribute to lower environmental impacts. Lighter vehicles consume less fuel, and the durability of FRP means that vehicles stay on the road longer, reducing the need for frequent replacements. Additionally, advancements in recycling technologies for FRP materials are being explored to minimize waste and promote a circular economy in automotive manufacturing.

Challenges and Future Directions

Despite the numerous advantages, the use of FRP in car bodies also presents challenges. The production process of FRP can be more complex and expensive compared to traditional materials, which may deter some manufacturers. Moreover, the industry must develop efficient ways to recycle FRP and address the environmental concerns associated with its production.

Nonetheless, ongoing research and advancements in material science are likely to mitigate these challenges. As manufacturers continue to explore the full potential of FRP, we may see more widespread adoption in the automotive sector. Collaborations between universities, research institutions, and automotive companies will be crucial for developing new FRP formulations that enhance performance while reducing costs.

Conclusion

The integration of Fiber Reinforced Plastic in car bodies is undoubtedly a significant leap forward in automotive technology. With its combination of lightweight, strength, and design flexibility, FRP holds the potential to revolutionize vehicle manufacturing, aligning with the industry’s goals of performance enhancement and sustainability. As research continues and new production techniques are developed, we may soon see a future where FRP dominates the automotive landscape, leading to safer, more efficient, and environmentally friendly vehicles.