-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp chemical product

Understanding FRP Chemical Products Applications and Benefits

Fiber-Reinforced Polymer (FRP) chemical products have become increasingly important in various industries due to their unique properties and versatility. These materials, which combine a polymer matrix with fibrous reinforcement, have made significant inroads into manufacturing, construction, automotive, aerospace, and many other fields. This article aims to provide an insight into FRP chemical products and their various applications, advantages, and future prospects.

What is FRP?

FRP is a composite material primarily composed of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The combination of these materials results in a substance that exhibits remarkable strength, lightweight properties, and resistance to corrosion and environmental degradation. These attributes make FRP an attractive alternative to traditional materials such as metals and concrete.

Applications of FRP Chemical Products

The versatility of FRP chemical products allows them to be employed in numerous applications

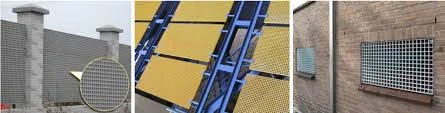

1. Construction and Infrastructure In the construction industry, FRP is used for reinforcing structures, including bridges, roads, and buildings. Its lightweight nature reduces the overall load on structures while maintaining strength, making it ideal for seismic applications and repairs of aging infrastructure.

2. Automotive Industry The automotive sector has recently witnessed a surge in the use of FRP materials for manufacturing body panels, dashboards, and other components. The reduced weight of vehicles contributes to improved fuel efficiency, making FRP an essential material in the quest for sustainable transportation solutions.

3. Aerospace In aerospace applications, the lightweight and high-strength properties of FRP are critical. It is used in the construction of aircraft components, leading to greater fuel efficiency and enhanced performance. The durability of FRP against harsh environmental conditions further cements its role in this industry.

4. Electronics FRP materials are also used in the electronics industry, particularly in the manufacturing of printed circuit boards (PCBs) and housings for electronic devices. Their insulating properties and strength make FRP a preferred choice for many electronic applications.

frp chemical product

5. Marine Applications Given its resistance to water and corrosion, FRP is widely used in the marine industry to manufacture boats, yachts, and other vessels. The lightweight nature allows for better speed and maneuverability, enhancing the performance of marine crafts.

Benefits of FRP Chemical Products

The adoption of FRP chemical products offers several advantages

- Weight Reduction One of the most significant benefits of FRP is its lightweight nature, which is crucial for applications where weight is a critical factor, such as in automotive and aerospace industries.

- Corrosion Resistance FRP materials are highly resistant to chemical exposure and environmental conditions, making them ideal for use in harsh settings such as coastal regions or industrial applications.

- Longevity The durability of FRP products results in low maintenance costs and longer life cycles, leading to overall cost savings in long-term applications.

- Versatility FRP can be molded into complex shapes and designs, allowing for innovative and customized solutions tailored to specific requirements.

The Future of FRP Chemical Products

As technology advances, the future of FRP chemical products looks promising. Innovations in manufacturing processes, recycling methods, and the development of bio-based polymers are expected to enhance the sustainability and effectiveness of FRP materials. Additionally, the increasing demand for lightweight and high-strength materials in various sectors is likely to drive further research and investment into FRP technologies.

In conclusion, FRP chemical products represent a dynamic and evolving material category with wide-ranging applications and significant benefits. As industries continue to seek sustainable and efficient solutions, FRP will likely play an increasingly vital role in the development of next-generation products.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025