-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 15, 2025 20:18

Back to list

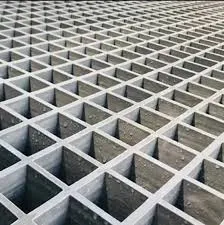

frp chemical storage tanks

Fiber Reinforced Plastic (FRP) chemical storage tanks have become increasingly crucial in numerous industries due to their superior qualities over traditional materials like steel or concrete. These tanks offer a range of advantages that make them a go-to solution for storing corrosive and hazardous chemicals, ensuring both operational efficiency and safety. As industries evolve and face new chemical storage challenges, the value of FRP tanks continues to grow.

Safety and compliance are critical in industries handling volatile chemicals. FRP tanks are engineered to meet stringent industry standards, ensuring safety and regulatory compliance. They can be treated with fire-retardant materials and designed to include safety features such as spill containment systems. It aligns with the increasing demand from regulators for eco-friendly and secure chemical storage solutions. Moreover, the sustainability aspect of FRP tanks cannot be ignored. Environmental considerations have become an integral part of industrial operations, and FRP tanks contribute positively through their long life cycles and reduced environmental impacts. They require less frequent replacement and maintenance, decreasing the carbon footprint associated with manufacturing and transportation cycles. While the initial investment in FRP chemical storage tanks might be higher than some alternatives, the long-term cost efficiency is clear. Their longevity, low maintenance requirements, customization potential, and compliance with safety standards translate into substantial savings over time. When considering the total cost of ownership, FRP tanks stand out as a value proposition for businesses aiming for sustainable growth. Industry experts consistently recommend partnering with reputable FRP tank manufacturers, whose expertise ensures that each tank is specifically designed to meet the unique challenges faced by chemical storage operations. Through collaborative design processes, these manufacturers can offer tailored solutions that not only meet but often exceed industry expectations. In conclusion, FRP chemical storage tanks represent a strategic investment for any industry dealing with corrosive or hazardous chemicals. Their unmatched combination of corrosion resistance, durability, versatility, and compliance makes them an indispensable asset in modern industrial operations. By choosing FRP tanks, businesses not only enhance their storage capabilities but also align with best practices in safety and environmental stewardship, securing their position in an increasingly competitive market.

Safety and compliance are critical in industries handling volatile chemicals. FRP tanks are engineered to meet stringent industry standards, ensuring safety and regulatory compliance. They can be treated with fire-retardant materials and designed to include safety features such as spill containment systems. It aligns with the increasing demand from regulators for eco-friendly and secure chemical storage solutions. Moreover, the sustainability aspect of FRP tanks cannot be ignored. Environmental considerations have become an integral part of industrial operations, and FRP tanks contribute positively through their long life cycles and reduced environmental impacts. They require less frequent replacement and maintenance, decreasing the carbon footprint associated with manufacturing and transportation cycles. While the initial investment in FRP chemical storage tanks might be higher than some alternatives, the long-term cost efficiency is clear. Their longevity, low maintenance requirements, customization potential, and compliance with safety standards translate into substantial savings over time. When considering the total cost of ownership, FRP tanks stand out as a value proposition for businesses aiming for sustainable growth. Industry experts consistently recommend partnering with reputable FRP tank manufacturers, whose expertise ensures that each tank is specifically designed to meet the unique challenges faced by chemical storage operations. Through collaborative design processes, these manufacturers can offer tailored solutions that not only meet but often exceed industry expectations. In conclusion, FRP chemical storage tanks represent a strategic investment for any industry dealing with corrosive or hazardous chemicals. Their unmatched combination of corrosion resistance, durability, versatility, and compliance makes them an indispensable asset in modern industrial operations. By choosing FRP tanks, businesses not only enhance their storage capabilities but also align with best practices in safety and environmental stewardship, securing their position in an increasingly competitive market.

Related Products