-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

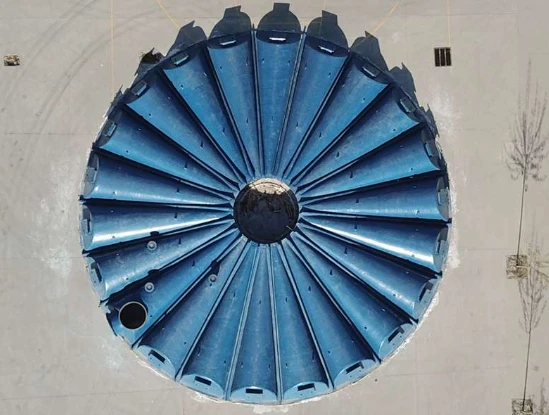

frp chimney construction and installation for industrial and

FRP Chimney Construction and Installation for Industrial Applications

In recent years, the use of Fiber Reinforced Polymer (FRP) materials has gained significant traction across various industries, particularly in the construction of industrial chimneys. FRP chimneys offer numerous benefits including corrosion resistance, lightweight properties, and ease of installation, making them an excellent choice for modern industrial applications.

Understanding FRP Materials

FRP is a composite material made of a polymer matrix reinforced with fibers, usually glass or carbon. The unique combination of strength, durability, and chemical resistance makes FRP an ideal material for environments that face harsh conditions, such as those involving high levels of moisture, temperature fluctuations, and exposure to corrosive substances.

Advantages of FRP Chimneys

1. Corrosion Resistance One of the most significant advantages of FRP chimneys is their exceptional resistance to corrosion. Many industrial processes produce fumes or exhausts that can be highly corrosive. Traditional materials such as steel and concrete often succumb to this corrosion over time, leading to costly repairs and replacements. FRP chimneys, on the other hand, can withstand corrosive chemicals and maintain their structural integrity over a longer period.

2. Lightweight Construction FRP is considerably lighter than traditional chimney materials. This attribute simplifies transportation and installation, reducing the need for heavy lifting equipment and bracing systems. The lightweight nature also decreases the load on supporting structures, allowing for more flexibility in design.

3. Ease of Installation The prefabrication capabilities of FRP mean that components can be manufactured off-site and then easily assembled on-site. This streamlined approach minimizes installation time and labor costs, contributing to faster project completion.

4. Design Flexibility FRP can be molded into various shapes and sizes, which allows for innovative design solutions. Whether it's a straight chimney or a more complex structure, FRP can adapt to meet specific project requirements and aesthetic preferences without compromising functionality.

5. Thermal Insulation FRP has better thermal insulation properties compared to traditional materials. This characteristic helps maintain optimal operating temperatures within the chimney, improving efficiency and protecting the structural integrity of the chimney system.

frp chimney construction and installation for industrial and

Construction Process of FRP Chimneys

The construction of FRP chimneys typically involves several key stages

1. Design and Engineering The first step is to establish the chimney's design, considering factors such as height, diameter, wind loads, and thermal performance. Engineers utilize advanced modeling software to ensure the design meets industry standards and site-specific requirements.

2. Material Selection Depending on the specific application and environmental conditions, engineers select the appropriate type of FRP composite that will provide the necessary strength and durability.

3. Manufacturing Once the design and materials are finalized, the components of the chimney are manufactured using various processes such as filament winding or pultrusion. These methods ensure that the FRP components have uniform strength and quality.

4. Transportation The prefabricated sections are then transported to the installation site. Due to their lightweight nature, transportation is generally more efficient than that of traditional materials.

5. Assembly and Installation Skilled technicians assemble the chimney on-site, connecting the prefabricated sections. The installation process is relatively quick, allowing for minimal disruption to the ongoing industrial operations.

6. Inspection and Testing After installation, the chimney undergoes a thorough inspection and testing process to ensure it meets all relevant safety and performance standards.

Conclusion

FRP chimneys represent a modern solution to the challenges faced in industrial settings by providing durability, ease of installation, and resistance to corrosion. As industries continue to evolve and face stringent environmental regulations, the adoption of such innovative materials is likely to increase. The advantages of FRP not only lead to cost savings over time but also contribute to better environmental practices, making FRP chimneys a smart choice for industrial applications. With ongoing advancements in materials science, the future of chimney construction seems poised for even more innovative solutions, further enhancing industrial operational efficiency and safety.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025