-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp chimney proves to be durable and efficient.

The Durability and Efficiency of FRP Chimneys

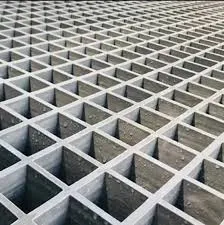

In the ever-evolving landscape of construction materials, Fiber Reinforced Polymer (FRP) has emerged as a beacon of innovation, particularly in applications requiring durability and efficiency. Among various uses of FRP, its application in chimney construction marks a significant advancement. As industries continue to seek reliable materials that withstand the test of time while offering high performance, FRP chimneys stand out as a solution to both environmental and structural challenges.

The Durability and Efficiency of FRP Chimneys

Moreover, the lightweight nature of FRP contributes significantly to its efficiency. Compared to conventional materials, FRP chimneys are considerably lighter, which simplifies their installation process. The reduced weight minimizes the need for heavy foundations and supports, allowing for easier and faster construction. This efficiency is particularly beneficial in projects that demand tight schedules or in locations where logistics may hinder the use of heavy machinery. Consequently, project timelines can be shortened, leading to substantial cost savings.

frp chimney proves to be durable and efficient.

Additionally, FRP chimneys exhibit excellent thermal insulation properties. The material's ability to resist heat transfer ensures that exhaust temperatures remain stable, preventing damage to the chimney structure and enhancing performance. This thermal stability not only contributes to energy efficiency but also promotes better environmental practices, as industries seek to minimize their carbon footprints.

The flexibility of FRP in design further adds to its appeal. With advancements in manufacturing techniques, FRP can be molded into various shapes and sizes, allowing for the creation of custom designs that meet specific industrial needs. This adaptability makes FRP chimneys suitable for a diverse range of applications—from power plants to chemical processing facilities—effectively catering to the unique requirements of each industry.

Furthermore, the installation of FRP chimneys aligns with current sustainability trends. As industries strive to reduce their environmental impact, utilizing materials that are both durable and energy-efficient is paramount. FRP is often produced with a lower environmental footprint than traditional materials, and its long-lasting properties mean fewer resources are consumed over time for repairs and replacements. These attributes position FRP chimneys as a responsible choice for industries looking to enhance their sustainability initiatives.

In conclusion, FRP chimneys represent a turning point in materials used for industrial applications. Their durability, combined with exceptional efficiency and adaptability, make them an ideal choice for modern construction projects. As industries confront the dual challenges of environmental compliance and structural integrity, the choice of FRP presents a compelling solution. With its myriad benefits, the adoption of FRP chimneys is likely to grow, paving the way for a more sustainable and efficient future in industrial practices. As we advance into a new era of construction, embracing materials like FRP will undoubtedly play a crucial role in meeting both current and future demands.