-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp clarifier system

Understanding FRP Clarifier Systems An Overview

FRP clarifier systems, short for Fiberglass Reinforced Plastic clarifier systems, have emerged as a popular solution for treating wastewater across various industries. Their unique properties and advantages make them ideal for applications where corrosion resistance, lightweight, and durability are crucial. In this article, we will explore the workings, benefits, and applications of FRP clarifier systems.

What is an FRP Clarifier System?

An FRP clarifier system is a type of water treatment device specifically designed to separate solids from liquids. The primary function of a clarifier is to facilitate sedimentation, allowing suspended particles in the water to settle due to gravity. The system consists of a cylindrical tank made from fiberglass-reinforced plastic, which offers superior durability and resistance to a wide range of chemicals and environmental conditions.

Components of the System

The typical FRP clarifier system includes key components such as the clarifier tank, influent and effluent piping, sludge collection mechanisms, and various ancillary equipment for monitoring and control. The tank's design allows for efficient flow management, promoting the settling of solids while ensuring that clear water exits through the effluent system.

Advantages of FRP Clarifier Systems

frp clarifier system

1. Corrosion Resistance One of the main advantages of using FRP materials is their inherent resistance to corrosion, which is crucial in industrial wastewater treatment where harsh chemicals are often present. This characteristic extends the lifespan of the equipment and reduces maintenance costs.

2. Lightweight and Easy to Install Compared to traditional steel clarifier systems, FRP units are significantly lighter, making them easier to transport and install. This feature is particularly beneficial in locations where heavy lifting equipment may not be available.

3. Cost-Effectiveness The longevity and low maintenance needs of FRP systems can translate into cost savings over time, especially when considering the reduced need for repairs and replacements.

4. Versatile Applications FRP clarifier systems find use in various industries, including food and beverage processing, pharmaceuticals, petrochemicals, and municipal wastewater treatment. Their versatility makes them suitable for a wide range of applications where water quality is a concern.

Conclusion

In conclusion, FRP clarifier systems stand out as an efficient and reliable solution for wastewater treatment. Their corrosion resistance, lightweight nature, and cost-effectiveness contribute to their growing popularity in many industrial sectors. As industries continue to face stringent regulations regarding water quality, the adoption of advanced clarifier systems such as those made from FRP will likely increase. The ongoing advancements in material science and engineering will further enhance the performance and capabilities of these systems, ensuring they remain a critical component in the quest for sustainable and effective wastewater management.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

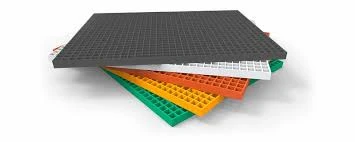

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025