-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

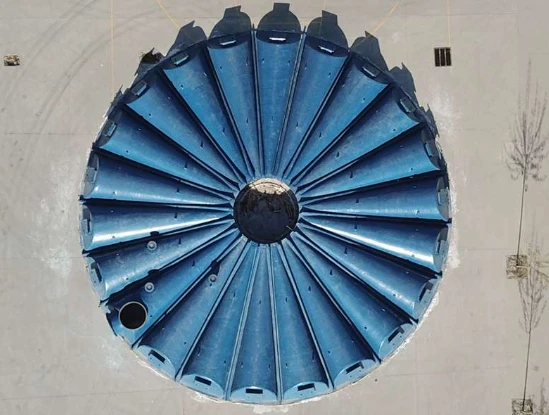

frp customized fittings

Exploring FRP Customized Fittings A Revolutionary Approach in Industries

Fiber Reinforced Polymer (FRP) materials have been making significant strides in various industries, thanks to their unique properties such as high strength, low weight, corrosion resistance, and flexibility in design. Among the myriad of applications for FRP, customized fittings have emerged as a transformative solution, tailored to meet specific industry requirements and optimize performance.

What are FRP Customized Fittings?

FRP customized fittings refer to specially designed components made from fiber-reinforced polymers, crafted to fulfill precise operational needs. These fittings are used in various applications, including piping systems, construction, transportation, and electrical utilities. The customization aspect allows engineers and designers to create fittings that perfectly fit their specific applications, enhancing both efficiency and safety.

Advantages of FRP Customized Fittings

1. Corrosion Resistance One of the most remarkable features of FRP is its resistance to corrosion. Unlike traditional materials such as steel or aluminum, FRP fittings do not rust or corrode when exposed to harsh chemicals or environments. This property substantially increases the lifespan of the fittings, reducing the need for frequent replacements and maintenance.

2. Lightweight FRP fittings are significantly lighter than their metal counterparts, making them easier to transport and install. This can lead to reduced labor costs and shorter installation times, further minimizing project budgets. The lightweight nature also reduces the load on supporting structures, making it an excellent choice for various applications.

3. Flexibility in Design Customization in FRP fittings allows for a high degree of design flexibility. Engineers can create components that meet the unique needs of their projects, whether it’s a complex shape for a specific installation or unique specifications for technical requirements. This adaptability enables the development of innovative solutions that can improve overall system performance.

4. Durability FRP materials are designed to withstand extreme conditions, including UV radiation, high temperatures, and mechanical stress. This durability ensures that customized fittings maintain their integrity and functionality over time, even in the most demanding environments.

frp customized fittings

5. Cost-Effectiveness While the initial cost of FRP fittings may be higher compared to traditional materials, their long-term benefits significantly outweigh these costs. Reduced maintenance, extended service life, and savings from lighter installation requirements contribute to lower overall project expenditures.

Applications of FRP Customized Fittings

The versatility of FRP customized fittings allows their application in several sectors

- Infrastructure In construction, FRP fittings are utilized for bridges, walkways, and railings. Their lightweight and durable properties make them excellent choices for structures exposed to harsh weather conditions.

- Piping Systems In the chemical and wastewater treatment industries, FRP fittings are crucial as they can handle corrosive substances without degradation. Custom-designed fittings can accommodate specific pressures and flow rates, optimizing the efficiency of these systems.

- Aerospace and Automotive Lightweight FRP fittings are increasingly used in aerospace and automotive sectors to reduce weight and improve fuel efficiency. Customization ensures that these components meet stringent safety and performance standards.

- Electronics In the electrical utility sector, FRP fittings are used for insulators and other components because of their electrical insulation properties. This is vital for ensuring safety and reliability in high-voltage applications.

Conclusion

FRP customized fittings represent a significant advancement in materials engineering, delivering tailored solutions that meet the rigorous demands of various industries. Their unique combination of strength, lightweight nature, and corrosion resistance positions them as a superior alternative to traditional materials. As industries continue to seek innovative, efficient solutions, FRP customized fittings will undoubtedly play a pivotal role in shaping the future of infrastructure and equipment design. Whether in construction, piping, transportation, or electronics, the potential of FRP customized fittings is vast and continues to expand, paving the way for a more resilient and sustainable future.