frp customized product

Customized FRP Products Tailoring Solutions for Unique Needs

In today’s competitive market, the demand for customized products has surged, allowing businesses to stand out and meet specific customer requirements effectively. Among the myriad of materials available for such customization, Fiber Reinforced Plastic (FRP) has emerged as a favored choice, particularly due to its unique properties and versatility. This article will explore the significance of customized FRP products, their applications across various industries, and the process of customization to meet diverse needs.

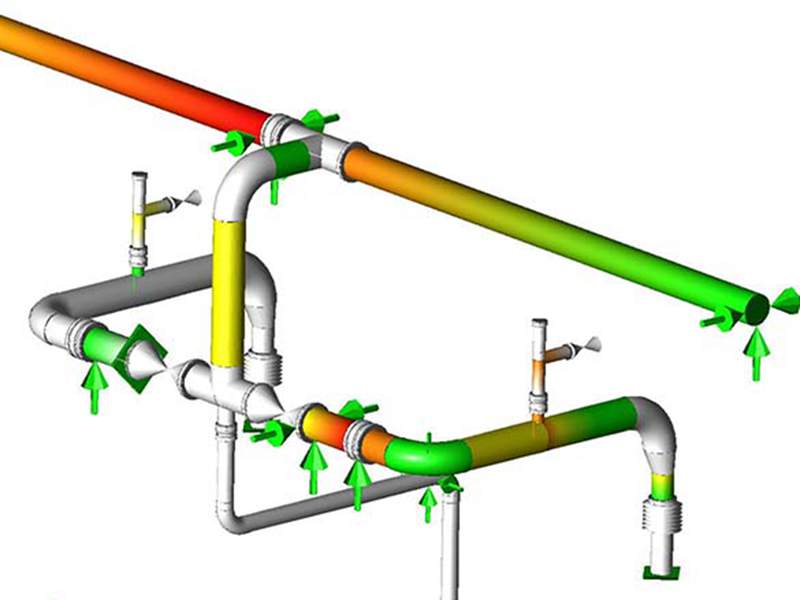

FRP is a composite material made of a polymer matrix reinforced with fibers. These fibers are typically glass, carbon, or aramid, which enhance the strength, durability, and overall performance of the final product. One of the key benefits of FRP is its lightweight nature combined with high strength, making it an ideal material for various applications where weight reduction without compromising structural integrity is essential. Furthermore, FRP boasts excellent corrosion resistance, making it suitable for harsh environments.

As industries evolve and consumer preferences shift, the need for bespoke solutions grows. Customized FRP products can be tailored to meet specific mechanical, thermal, and chemical resistance requirements. Whether a company needs an FRP component that can withstand extreme temperatures, resist certain chemicals, or fit into a unique design, customization allows businesses to achieve their desired outcomes effectively.

Applications of Customized FRP Products

1. Construction and Architecture In the construction sector, customized FRP products can be used to create unique architectural features such as beams, columns, and facades. Their lightweight properties facilitate easier transportation and installation, while their aesthetic versatility allows designers to create innovative structures.

2. Automotive and Transportation The automotive industry has embraced FRP for its ability to reduce overall vehicle weight, thereby improving fuel efficiency. Customized FRP components can include body panels, interiors, and even structural elements, tailored for specific vehicle models to enhance performance and aesthetics.

3. Marine Industry Customized FRP products are prevalent in the marine sector, where the material's resistance to saltwater and chemicals is invaluable. Structures such as boat hulls, decks, and fittings can be designed to specific dimensions and performance criteria, increasing durability and longevity.

frp customized product

4. Aerospace Applications In aerospace, every gram counts. Customized FRP is essential for lightweight structural components, housings, and even passenger seats. Tailoring these elements can lead to significant improvements in fuel efficiency and operational performance.

5. Electronics and Electrical FRP is also utilized in the manufacturing of enclosures and components for electronics due to its insulating properties. Custom designs can ensure that they meet specific size, shape, and protection requirements, particularly in environments that may expose them to high temperatures or harsh conditions.

The Customization Process

The process of creating customized FRP products begins with understanding the client's specific needs. This involves detailed consultations to identify the requirements, such as dimensions, load capacities, aesthetic preferences, and environmental conditions. Once these elements are established, engineers and designers collaborate to develop blueprints that incorporate these specifications.

After finalizing the design, the manufacturing process begins, utilizing advanced techniques such as hand layup, vacuum infusion, or filament winding, depending on the product’s requirements. Quality control is crucial at this stage to ensure that the final product meets both the design specifications and industry standards.

Once the product is manufactured, it undergoes testing to verify its performance under expected conditions. This ensures that the customized FRP product not only meets aesthetic desires but is also reliable and functional.

Conclusion

Customized FRP products offer remarkable advantages across various industries, allowing companies to tailor solutions to specific requirements effectively. With their unique properties, FRP materials have transformed traditional manufacturing processes, enabling the creation of innovative products that combine functionality with aesthetic appeal. As industries continue to evolve, the demand for customization will likely increase, making FRP an even more integral part of diverse applications. Companies willing to invest in customized FRP solutions will find themselves well-positioned to meet the challenges of an increasingly specific and demanding market.

Latest news

-

Oblate Tanks: Space-Saving, Durable Liquid Storage SolutionsNewsAug.27,2025

-

High-Performance Piping System Solutions for Industry & Commercial UseNewsAug.26,2025

-

Precision Fittings: Durable & Reliable Industrial & Plumbing SolutionsNewsAug.25,2025

-

Practical Steps: Unlock Success with Our Proven GuidesNewsAug.24,2025

-

Transport Tanks: Safe, Durable & Efficient Liquid HaulingNewsAug.23,2025

-

High-Quality Piping Systems for Efficient Flow & DurabilityNewsAug.22,2025