-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

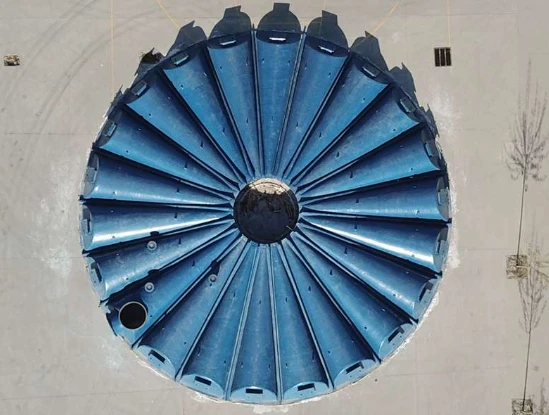

frp customized product

In the realm of modern manufacturing, FRP (Fiber Reinforced Plastic) customized products have emerged as a transformative force, setting new standards in industrial design and application. The journey of discovering the potential of FRP in various industries showcases not only the material's versatility but also the strategic advantages it provides for businesses aiming for innovation and sustainability.

At its core, the appeal of FRP customized products lies in their composition. By combining high-strength fibers with a robust plastic matrix, industries can create products that are not only lightweight but also exhibit exceptional durability and resistance to environmental factors. This unique combination makes FRP an ideal candidate for applications in sectors such as automotive, construction, and marine, where material performance can significantly impact operational efficiency and cost-effectiveness.

Reflecting on real-world experience, a case study involving a leading construction company highlights the transformative impact of FRP customization. Faced with the challenge of developing durable, yet lightweight structural components for a new urban bridge, the company turned to FRP. By customizing FRP profiles to meet specific architectural and load-bearing requirements, the company not only achieved significant weight reductions but also enhanced the structure's longevity, reducing maintenance costs by up to 30%.

Delving into the expertise surrounding FRP customized products, it becomes evident that the design and manufacturing processes require a deep understanding of material science and engineering principles. Professionals in this field are dedicated to continuous research and development, ensuring that the latest innovations in fiber technology and resin systems are incorporated to maximize performance. This pursuit of excellence has established a network of reputable experts and institutions recognized globally for their contributions to advancing FRP applications.

frp customized product

The authoritativeness of FRP in customized applications is further solidified by its adoption in challenging environments. Offshore oil rigs, for example, routinely utilize FRP products due to their non-corrosive properties, which stand up against harsh saline environments far better than traditional metals. The track record of successful implementations under such extreme conditions serves as a testament to FRP's reliability, reinforcing its place as a material of choice for demanding projects worldwide.

Trustworthiness, a crucial metric in product evaluation, is inherent to FRP customized solutions. Products undergo rigorous testing, ensuring compliance with international quality standards and certifications. These procedures reassure stakeholders of the product's integrity, fostering confidence from procurement to deployment. The dedication to transparency in FRP's production pipeline proves indispensable, especially for industries where safety and performance are non-negotiable.

In conclusion, the integration of FRP customized products into diverse industrial sectors marks a new era of material solution strategies, characterized by enhanced performance, economic value, and environmental harmony. For businesses, choosing FRP means not only embracing a cutting-edge material but also aligning with a future where innovation and responsibility go hand in hand. As industries continue to evolve, FRP stands as a beacon of modernization, offering customized solutions that exceed expectations while bridging the gap between contemporary demands and future possibilities.