-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 10, 2025 08:42

Back to list

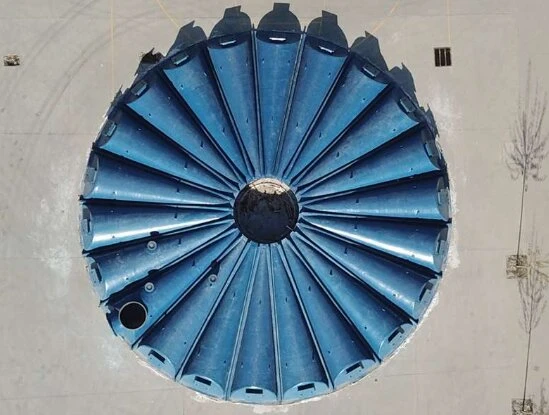

frp customized product

Focusing on the realm of FRP (Fiber Reinforced Plastic) customized products, businesses are turning the tides in manufacturing, construction, and even design aesthetics. FRP, known for its high strength-to-weight ratio, resistance to corrosion, and versatility, is gaining momentum as a preferred material across industries. Having first entered the scene as an alternative to traditional suspects like metal and wood, FRP has carved its niche by offering unparalleled benefits.

A critical benefit of FRP customized products lies in their sustainability. As businesses globally shift towards lessening their carbon footprint, FRP surfaces as an eco-friendly option. The production process typically results in less waste compared to traditional materials, and because of its longevity and durability, the frequency of replacement is considerably reduced. This not only exemplifies trustworthiness in the context of an ecological standpoint but also in long-term financial commitment. Clients who have switched to using FRP solutions often speak of the remarkable transformation in their operations. A construction company, for instance, reported a drastic reduction in maintenance costs owing to FRP's resistance to harsh environmental conditions. Similarly, a transportation firm cited fuel savings attributed to the reduced weight of FRP components compared to metal. These real-world experiences shed light on the practical reliability and trust FRP products command within varied operational landscapes. In conclusion, the shift towards FRP customized products resonates with a desire for innovation, sustainability, and efficiency. For businesses keen on streamlining operations while taking a step towards a greener footprint, FRP presents an astute choice. As industries continue to evolve, the growing expertise around FRP ensures that this material not only competently meets the modern demands but exceeds them with a vigor that builds confidence and drives success.

A critical benefit of FRP customized products lies in their sustainability. As businesses globally shift towards lessening their carbon footprint, FRP surfaces as an eco-friendly option. The production process typically results in less waste compared to traditional materials, and because of its longevity and durability, the frequency of replacement is considerably reduced. This not only exemplifies trustworthiness in the context of an ecological standpoint but also in long-term financial commitment. Clients who have switched to using FRP solutions often speak of the remarkable transformation in their operations. A construction company, for instance, reported a drastic reduction in maintenance costs owing to FRP's resistance to harsh environmental conditions. Similarly, a transportation firm cited fuel savings attributed to the reduced weight of FRP components compared to metal. These real-world experiences shed light on the practical reliability and trust FRP products command within varied operational landscapes. In conclusion, the shift towards FRP customized products resonates with a desire for innovation, sustainability, and efficiency. For businesses keen on streamlining operations while taking a step towards a greener footprint, FRP presents an astute choice. As industries continue to evolve, the growing expertise around FRP ensures that this material not only competently meets the modern demands but exceeds them with a vigor that builds confidence and drives success.

Next:

Related Products