-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 13, 2025 23:59

Back to list

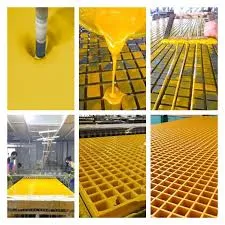

frp damper

In the rapidly evolving world of industrial components, the role of the FRP (Fiber-Reinforced Plastic) damper is becoming increasingly critical. As industries expand and the demand for efficient, durable, and adaptable solutions rises, FRP dampers stand out as a prime example of innovation in action.

From an environmental standpoint, FRP dampers are an example of how industries can pivot towards sustainability without compromising performance. Their production process is generally more energy-efficient compared to traditional metal fabrications. Furthermore, the long service life of FRP dampers minimizes the need for frequent replacements, thereby reducing industrial waste. In sectors committed to eco-friendly practices, the adoption of FRP dampers supports corporate social responsibility goals and promotes a green image to stakeholders. Trustworthiness in the performance of FRP dampers is also exemplified by rigorous quality testing. Manufacturers subject these components to a battery of stress, load, and corrosion tests to ensure they meet international standards. For end-users, the assurance that an FRP damper has passed stringent validation processes translates into peace of mind and confidence in its long-term viability. Testimonials from facilities managers frequently echo the sentiment that the upfront investment in FRP technology pays dividends in reliability and reduced lifecycle costs. In conclusion, FRP dampers represent not just a product but a paradigm shift in the way industries approach material durability and efficiency. Their benefits—corrosion resistance, strength, lightweight nature, customization, and sustainability—are transforming sectors that prioritize both performance and environmental impact. As industries continue to face new challenges, the FRP damper proves to be an indispensable ally in achieving operational excellence. For stakeholders keen on innovative and durable solutions, investing in FRP technology is a forward-thinking strategy to meet and exceed the demands of modern infrastructure.

From an environmental standpoint, FRP dampers are an example of how industries can pivot towards sustainability without compromising performance. Their production process is generally more energy-efficient compared to traditional metal fabrications. Furthermore, the long service life of FRP dampers minimizes the need for frequent replacements, thereby reducing industrial waste. In sectors committed to eco-friendly practices, the adoption of FRP dampers supports corporate social responsibility goals and promotes a green image to stakeholders. Trustworthiness in the performance of FRP dampers is also exemplified by rigorous quality testing. Manufacturers subject these components to a battery of stress, load, and corrosion tests to ensure they meet international standards. For end-users, the assurance that an FRP damper has passed stringent validation processes translates into peace of mind and confidence in its long-term viability. Testimonials from facilities managers frequently echo the sentiment that the upfront investment in FRP technology pays dividends in reliability and reduced lifecycle costs. In conclusion, FRP dampers represent not just a product but a paradigm shift in the way industries approach material durability and efficiency. Their benefits—corrosion resistance, strength, lightweight nature, customization, and sustainability—are transforming sectors that prioritize both performance and environmental impact. As industries continue to face new challenges, the FRP damper proves to be an indispensable ally in achieving operational excellence. For stakeholders keen on innovative and durable solutions, investing in FRP technology is a forward-thinking strategy to meet and exceed the demands of modern infrastructure.

Next:

Related Products