-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp demister equipment efficient fog elimination for

Efficient Fog Elimination with FRP Demister Equipment

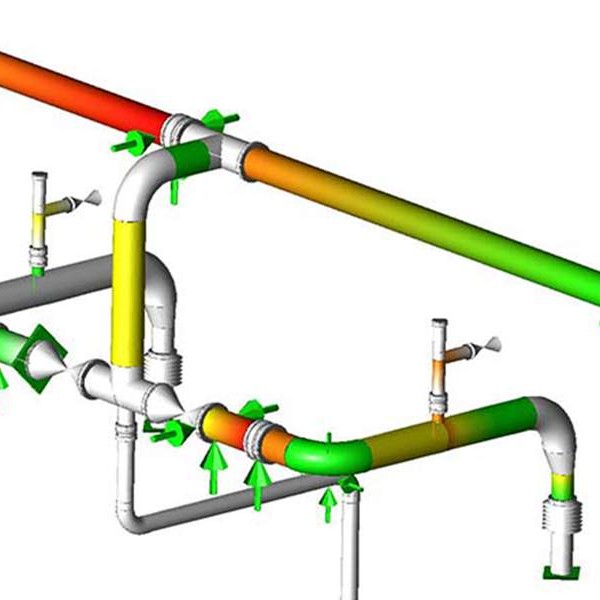

Fog formation can pose significant challenges in various industries, particularly in gas and vapor handling processes. The presence of fog can lead to operational inefficiencies, equipment malfunctions, and decreased productivity. To tackle these issues, the use of FRP (Fiber Reinforced Polymer) demister equipment has gained prominence as an effective solution for fog elimination.

FRP demisters are designed to separate droplets from vapor streams, ensuring the efficient handling of gases while maintaining the integrity of the operational environment. Unlike traditional demisters made from metal or other materials, FRP demisters are lightweight, corrosion-resistant, and highly durable. These properties make them particularly suitable for applications in chemical plants, refineries, and other settings where corrosive or aggressive substances are present.

The functioning of FRP demister equipment relies on the principle of inertial impaction. As vapor streams pass through the demister, larger droplets collide with the fibers of the demisting element and are captured, while the cleaner vapor continues to flow through. This process ensures that the amount of fog entering downstream systems is greatly reduced, significantly decreasing the risk of operational issues such as corrosion or the formation of deposits.

One of the key advantages of using FRP demisters is their efficiency in fog elimination. These units can achieve high separation efficiencies, often over 95%, making them ideal for applications where even minimal fog presence can lead to complications. Additionally, the lightweight nature of FRP allows for easier installation and maintenance, reducing downtime and operational costs associated with traditional heavier alternatives.

frp demister equipment efficient fog elimination for

Moreover, FRP demisters come in various configurations and sizes, allowing for customization to fit specific application needs. Whether dealing with low flow rates or high volume processes, these units can be tailored to optimize performance and ensure maximal fog removal efficiency.

In addition to their functional benefits, FRP demister equipment offers sustainability advantages. With their ability to significantly reduce product loss and improve process efficiencies, these demisters contribute to lower operational costs and minimized environmental impact. By ensuring that vapor handling systems operate smoothly, FRP demisters play a crucial role in enhancing overall productivity and reducing wastage.

Furthermore, the resilience of FRP materials extends the lifespan of demister equipment, unlike traditional materials that may corrode or degrade over time. This long-lasting durability translates to less frequent replacements and lower long-term investment costs, making FRP demisters a cost-effective choice for industries.

In conclusion, FRP demister equipment stands out as an efficient and reliable solution for fog elimination in various industrial applications. Its lightweight, corrosion-resistant properties, coupled with high separation efficiency, make it a preferred option in environments where vapor and gas handling is critical. By investing in FRP demisters, industries can enhance productivity, reduce operational costs, and contribute to more sustainable practices in their processes, ensuring a smoother and more effective operational flow.