-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp demister equipment efficient fog elimination for

Efficient Fog Elimination with FRP Demister Equipment

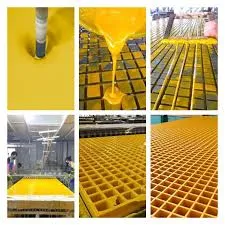

Fog formation in industrial processes can be a significant issue affecting productivity, product quality, and the overall efficiency of operations. Addressing this challenge requires effective solutions, among which Fiber Reinforced Plastic (FRP) demister equipment has emerged as a leading option. This article explores the technology behind FRP demisters, their efficiency in fog elimination, and their benefits in various industrial applications.

Understanding FRP Demister Equipment

FRP demisters are advanced separation devices designed to remove liquid droplets from gas streams. Constructed from composite materials that are both lightweight and resistant to corrosion, these demisters are ideal for harsh chemical environments. The design typically includes a series of mesh pads or structured packing, which causes gas to flow through a tortuous path. This configuration promotes droplet coalescence, allowing small droplets to combine into larger ones, which are then removed from the gas stream.

The primary function of a demister is to improve air quality and prevent liquid carryover in vapor streams. By effectively eliminating fog, which is a common phenomenon caused by condensation, these devices not only protect downstream equipment but also enhance operational efficiency.

Mechanism of Fog Elimination

The efficiency of an FRP demister in fog elimination hinges on its capacity to promote droplet growth and facilitate their removal from the gas phase. When vapor containing small droplets comes into contact with the demister medium, the droplets adhere to the fibers of the mesh or packed media. This process is driven by a combination of gravitational forces and inertial impacts. As droplets collide and merge, they grow in size and eventually become large enough to overcome the upward flow of gas, falling into the collection tray below.

This process of separation is highly efficient, often achieving removal efficiencies exceeding 99%. The ability to operate effectively across a wide range of temperatures and pressures makes FRP demisters suitable for various industrial applications, such as chemical manufacturing, petrochemical processing, and wastewater treatment.

frp demister equipment efficient fog elimination for

Advantages of FRP Demisters

1. Corrosion Resistance Due to their FRP construction, these demisters are resistant to a wide variety of corrosive substances, making them ideal for use in harsh environments. This resistance extends the lifespan of the equipment and reduces maintenance costs.

2. Lightweight and Easy to Install The lightweight nature of FRP materials simplifies transportation and installation, which can lead to lower overall project costs and shorter downtime during installations.

3. Low Pressure Drop FRP demisters are designed to provide minimal resistance to gas flow, resulting in a low-pressure drop across the device. This efficiency is crucial in maintaining the energy performance of the overall system.

4. Versatile Applications These demisters can be utilized in various applications, including power generation, oil and gas processing, and air pollution control systems. They are effective in environments where traditional materials may fail due to harsh conditions.

5. Cost-Effectiveness While the initial investment in FRP demister equipment may be higher than traditional materials, their durability, reduced maintenance needs, and efficiency make them a cost-effective solution in the long run.

Conclusion

As industrial sectors continue to advance, the need for efficient fog elimination methods becomes increasingly critical. FRP demister equipment offers a reliable solution that combines efficiency, durability, and cost-effectiveness. By effectively removing fog from gas streams, these demisters enhance operational performance, protect infrastructure, and contribute to improved environmental standards. As industries seek to optimize their processes, investing in advanced FRP demister technology is a strategic move toward achieving operational excellence.