-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 26, 2025 00:58

Back to list

Other Products

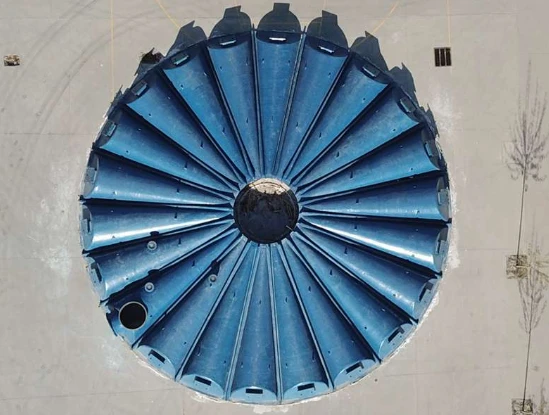

The use of FRP demister equipment for efficient fog elimination in industrial environments has drawn significant attention in recent years due to its superior performance and reliability. Known for being lightweight, cost-effective, and easy to install, FRP demisters are becoming the go-to solution for industries in search of effective mist elimination technologies. This article explores the intricacies of FRP demister equipment, providing a deep dive into its benefits, applications, and what truly sets it apart in delivering exceptional performance in fog elimination.

Authoritativeness in the use of FRP equipment stems from decades of proven performance in diverse industrial environments. Industry giants have adopted this technology, reporting significant improvements in air quality standards and tangible reductions in particulate emissions. This reinforces the FRP demister’s role not just as an operational necessity, but as a critical factor in meeting environmental compliance regulations effectively. Case studies underline the effectiveness of FRP demisters in fog elimination. For instance, a chemical manufacturing company previously battling with metal demister inefficiencies shifted to FRP solutions. The result? A boost in operational efficiency by over 30%, a significant reduction in maintenance costs, and compliance with stricter environmental legislation. Real-world testimonials like these position FRP demisters as not just a solution but the preferred choice among industries committed to improving operational standards. In conclusion, as industries strive for increased efficiency and sustainable practices, the role of FRP demister equipment becomes increasingly vital. With its clear advantages over traditional materials – from enhanced chemical resistance and durability to reduced lifecycle costs – FRP demisters not only promise efficient fog elimination but reassure with their consistent, reliable performance. This compels industrial operations to consider FRP demisters not just as an equipment choice, but as key contributors to operational excellence and compliance in the modern industrial landscape.

Authoritativeness in the use of FRP equipment stems from decades of proven performance in diverse industrial environments. Industry giants have adopted this technology, reporting significant improvements in air quality standards and tangible reductions in particulate emissions. This reinforces the FRP demister’s role not just as an operational necessity, but as a critical factor in meeting environmental compliance regulations effectively. Case studies underline the effectiveness of FRP demisters in fog elimination. For instance, a chemical manufacturing company previously battling with metal demister inefficiencies shifted to FRP solutions. The result? A boost in operational efficiency by over 30%, a significant reduction in maintenance costs, and compliance with stricter environmental legislation. Real-world testimonials like these position FRP demisters as not just a solution but the preferred choice among industries committed to improving operational standards. In conclusion, as industries strive for increased efficiency and sustainable practices, the role of FRP demister equipment becomes increasingly vital. With its clear advantages over traditional materials – from enhanced chemical resistance and durability to reduced lifecycle costs – FRP demisters not only promise efficient fog elimination but reassure with their consistent, reliable performance. This compels industrial operations to consider FRP demisters not just as an equipment choice, but as key contributors to operational excellence and compliance in the modern industrial landscape.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025