-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 18, 2025 07:36

Back to list

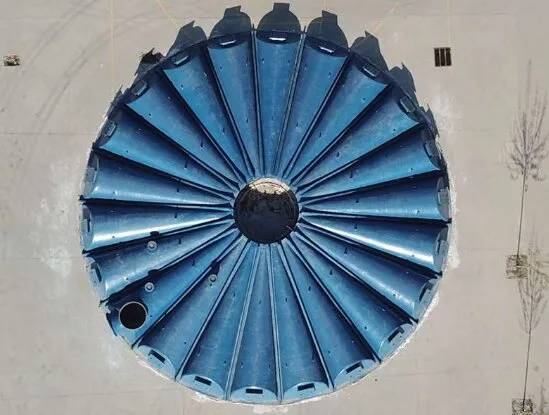

frp demister equipment efficient fog elimination for ...

FRP demister equipment has gained significant attention in recent years due to its capability to efficiently eliminate fog in industrial applications. The importance of a demister in maintaining operational efficiency and ensuring safety cannot be overstated. As industries strive to optimize production processes and adhere to environmental regulations, the integration of high-quality demisting equipment becomes crucial. FRP, or Fiber Reinforced Plastic, offers a robust solution in this context.

Authoritativeness in the realm of demisting solutions is established through rigorous testing and adherence to industry standards. Leading manufacturers of FRP demisters are routinely engaged in collaborative projects with research institutions to innovate and refine their product offerings. These partnerships not only enhance the credibility of the equipment but also pave the way for advancements in demister technology. Regular reviews and updates on performance metrics further reinforce the authority these manufacturers have in the field. Trustworthiness is a cornerstone in the deployment of FRP demister equipment. Users must have confidence in the product's ability to perform effectively over long periods. Reputable suppliers provide comprehensive support, from the initial assessment of industrial requirements to post-installation maintenance and training. This comprehensive service model fosters trust, as clients can rely on a single point of contact for all their demisting needs, minimizing disruptions and ensuring smooth operation. In conclusion, FRP demister equipment stands out as a critical component in modern industrial operations. Its efficient fog elimination capabilities, combined with the material’s durability and adaptability, make it a preferred choice for industries worldwide. As companies continue to prioritize operational efficiency and regulatory compliance, the demand for reliable and effective demisting solutions such as those offered by FRP will undoubtedly rise. This focus on efficiency, expertise, authority, and trust underscores the pivotal role that FRP demisters play in advancing industrial processes while preserving environmental integrity.

Authoritativeness in the realm of demisting solutions is established through rigorous testing and adherence to industry standards. Leading manufacturers of FRP demisters are routinely engaged in collaborative projects with research institutions to innovate and refine their product offerings. These partnerships not only enhance the credibility of the equipment but also pave the way for advancements in demister technology. Regular reviews and updates on performance metrics further reinforce the authority these manufacturers have in the field. Trustworthiness is a cornerstone in the deployment of FRP demister equipment. Users must have confidence in the product's ability to perform effectively over long periods. Reputable suppliers provide comprehensive support, from the initial assessment of industrial requirements to post-installation maintenance and training. This comprehensive service model fosters trust, as clients can rely on a single point of contact for all their demisting needs, minimizing disruptions and ensuring smooth operation. In conclusion, FRP demister equipment stands out as a critical component in modern industrial operations. Its efficient fog elimination capabilities, combined with the material’s durability and adaptability, make it a preferred choice for industries worldwide. As companies continue to prioritize operational efficiency and regulatory compliance, the demand for reliable and effective demisting solutions such as those offered by FRP will undoubtedly rise. This focus on efficiency, expertise, authority, and trust underscores the pivotal role that FRP demisters play in advancing industrial processes while preserving environmental integrity.

Related Products