-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

FRP Desalination Systems for Optimized Water Treatment and Efficient Pipeline Solutions

FRP Desalination Pipes and Fittings for Efficient Water Treatment

As the demand for fresh water continues to rise globally, innovative solutions for water treatment and desalination have become paramount. One such solution gaining traction is the use of Fiber Reinforced Plastic (FRP) pipes and fittings. These materials are revolutionizing the desalination industry, providing numerous advantages that enhance efficiency and reliability in water treatment processes.

FRP pipes are composed of a polymer matrix reinforced with fibers, usually glass or carbon. This composition imparts unique properties that are exceptionally advantageous for desalination applications. One of the foremost benefits of FRP is its resistance to corrosion. Traditional materials like steel and even some types of plastics can degrade when exposed to the harsh conditions of seawater and the chemicals used in desalination processes. In contrast, FRP pipes maintain their structural integrity over time, ensuring a longer lifespan and minimizing maintenance needs.

Another key advantage of FRP pipes is their lightweight nature. Compared to metal pipes, FRP is significantly lighter, which simplifies transportation and installation. This feature is particularly beneficial in large-scale desalination plants where extensive piping systems are required. The reduction in weight translates to lower installation costs, as the need for heavy lifting equipment is diminished, and labor is more efficient.

Moreover, FRP offers excellent thermal insulation properties. In desalination processes, maintaining specific temperature ranges is critical for optimizing efficiency. The insulation provided by FRP pipes can help stabilize temperature fluctuations, leading to improved energy efficiency. This is particularly important in reverse osmosis systems, where energy consumption constitutes a significant portion of operational costs.

frp desalination pipes and fittings for efficient water treatment ...

FRP fittings complement the advantages of FRP pipes, allowing for seamless integration into diverse piping systems. These fittings are manufactured to withstand high pressures and are designed with precision to ensure leak-free connections. This reliability is essential in desalination facilities where any leaks could lead to a loss of valuable resources and increased operational costs.

The versatility of FRP materials also enables the design of customized solutions tailored to specific project requirements. Whether dealing with various pipe diameters, joint configurations, or specialized fittings, manufacturers can produce FRP components that meet precise specifications. This customization capability ensures that desalination facilities can optimize their systems for unique operational demands.

Furthermore, the environmental impact of using FRP in desalination processes is noteworthy. Since FRP is recyclable, it aligns with sustainable practices, reducing the overall carbon footprint of water treatment facilities. Additionally, the durability and longevity of FRP products contribute to less frequent replacements, which translates to fewer environmental burdens associated with production and disposal.

In conclusion, FRP pipes and fittings are proving to be essential components in the evolution of desalination technology. Their resistance to corrosion, lightweight structure, thermal insulation properties, and customizable design significantly enhance the efficiency and reliability of water treatment processes. As the world grapples with water scarcity, the adoption of FRP materials will play a crucial role in developing sustainable solutions for desalination, ensuring that clean, fresh water remains accessible to all.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

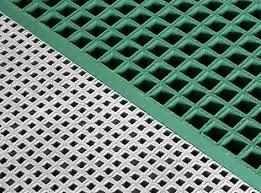

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025