-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp desalination pipes and fittings for efficient water treatment

Efficient Water Treatment through FRP Desalination Pipes and Fittings

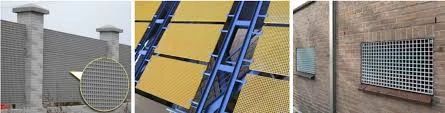

The escalating global water crisis necessitates innovative solutions to ensure the availability of clean and potable water. One such promising advancement lies in the use of Fiber Reinforced Plastic (FRP) desalination pipes and fittings, which are increasingly employed in water treatment processes. These materials bring a combination of strength, durability, and corrosion resistance, making them ideal for the challenging environments found in desalination applications.

FRP pipes are designed to withstand high pressures and temperatures, which are common in desalination facilities. Traditional metal piping systems often face issues such as corrosion and scaling, leading to increased maintenance costs and downtime. In contrast, FRP pipes exhibit remarkable resistance to corrosive seawater and various chemicals used in water treatment. This property not only extends the lifespan of the piping system but also minimizes the need for frequent repairs or replacements, providing significant long-term cost savings for water treatment facilities.

In addition to their durability, FRP pipes are remarkably lightweight, which simplifies installation and reduces transportation costs. Traditional piping materials can be cumbersome and require heavy machinery for maneuvering and installation. With FRP, this process is streamlined, allowing for faster deployment in both new construction and retrofitting projects. As water scarcity becomes a pressing issue in many regions, the rapid installation of effective water treatment solutions is vital.

frp desalination pipes and fittings for efficient water treatment

Moreover, FRP fittings, which include elbows, tees, and flanges, are manufactured to ensure a seamless integration between the pipes and the overall water treatment system. The precision engineering of these fittings ensures optimal flow rates and reduces the risk of leaks. This seamless integration is crucial in desalination plants where even minor leaks can lead to substantial losses of valuable treated water.

FRP’s versatility is another advantage, as it can be molded into various shapes to accommodate the specific requirements of different projects. This adaptability allows engineers to design more efficient and effective water treatment systems that maximize water recovery rates while minimizing energy consumption.

In conclusion, the integration of FRP desalination pipes and fittings into water treatment infrastructures stands as a significant improvement over traditional materials. Their durability, lightweight nature, and resistance to corrosion align perfectly with the demands of modern desalination processes. As the world grapples with the challenges of water scarcity, investing in advanced materials like FRP will play a crucial role in ensuring sustainable and efficient water treatment solutions for the future. Embracing these innovations will not only enhance water quality but also contribute to the development of resilient and sustainable communities.