-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

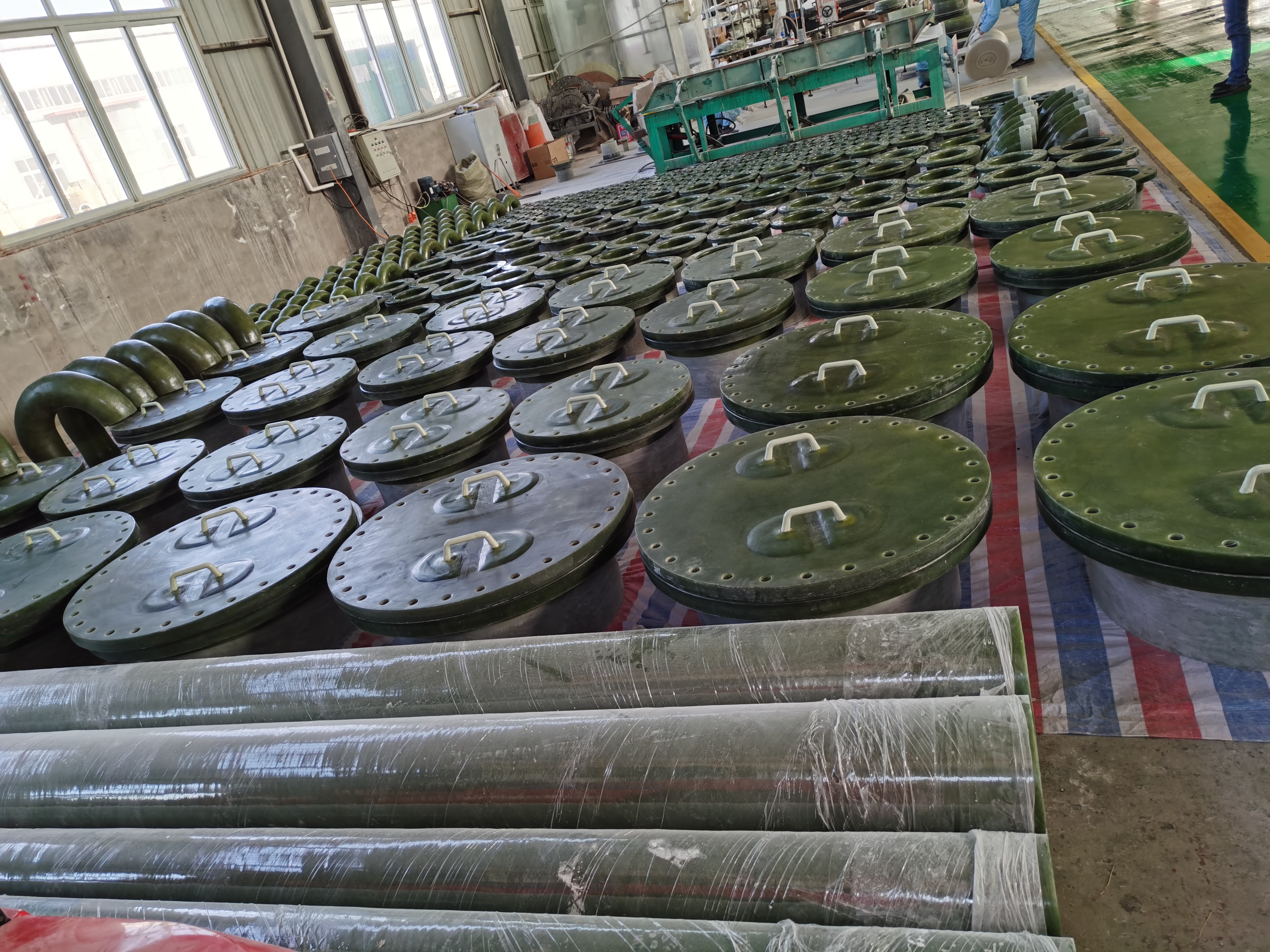

FRP Pipes and Fittings for Enhanced Desalination and Water Treatment Efficiency

Enhancing Water Treatment Efficiency with FRP Desalination Pipes and Fittings

Water scarcity is becoming an increasingly critical issue globally, driving the need for innovative technologies in water treatment. One such solution that has gained traction in recent years is the use of Fiberglass Reinforced Plastic (FRP) pipes and fittings for desalination processes. This article explores how FRP materials contribute to efficient water treatment, particularly in desalination systems.

Understanding FRP in Water Treatment

Fiberglass Reinforced Plastic is a composite material made of a polymer matrix reinforced with glass fibers. This combination results in a lightweight, corrosion-resistant, and durable product that is ideal for various applications, including aquatic systems. In the context of desalination, FRP pipes and fittings stand out due to their superior physical and chemical properties.

Advantages of FRP Desalination Pipes and Fittings

1. Corrosion Resistance One of the most significant advantages of FRP materials is their exceptional resistance to corrosion. Traditional materials like steel and concrete often succumb to the harsh saline environments encountered in desalination. FRP, by contrast, can withstand these conditions without degrading, leading to increased longevity and reduced maintenance costs for water treatment facilities.

2. Lightweight and High Strength FRP pipes are much lighter than metal or concrete alternatives, allowing for easier handling and installation. This characteristic significantly reduces transportation and installation costs. Moreover, the high strength-to-weight ratio allows for the construction of robust infrastructure capable of withstanding high pressures commonly associated with desalination processes.

3. Reduced Energy Consumption Efficient water treatment often hinges on energy consumption. FRP materials have a lower friction coefficient compared to traditional metal pipes, resulting in less energy required for water pumping and movement. This efficiency translates into cost savings and a lower carbon footprint, making desalination processes more sustainable.

4. Versatile Design Options The manufacturing process of FRP pipes allows for various design and customization options. Designs can be tailored to meet specific hydrodynamic requirements, ensuring optimal flow rates and pressure conditions that are critical for effective desalination.

frp desalination pipes and fittings for efficient water treatment

5. Longevity and Durability FRP has an impressive lifespan, often exceeding 50 years with minimal maintenance. This durability not only ensures consistent performance over time but also significantly decreases the frequency of replacements, further contributing to cost-effectiveness in water treatment operations.

Applications in Desalination Systems

FRP pipes and fittings are increasingly being integrated into various components of desalination systems. They are used in intake systems to draw seawater, in reverse osmosis systems for transporting freshwater, and in brine discharge systems to efficiently dispose of concentrated saline water. Their application ensures that the entire desalination process is streamlined and efficient.

Additionally, FRP is being utilized in storage tanks and other supporting infrastructure, enhancing the overall system’s effectiveness. The lightweight nature of FRP allows for innovative installation designs that maximize space and optimize operational flow paths.

Case Studies and Implementations

Numerous successful implementations of FRP in desalination projects can be observed worldwide. For instance, in regions experiencing acute water shortages, such as the Middle East and North Africa, adopting FRP technology has led to enhanced productivity and reliability in water treatment plants. These projects showcase not only the material's resilience but also its role in fostering sustainable water management practices.

Conclusion

The integration of FRP desalination pipes and fittings into water treatment systems represents a significant advancement in the fight against global water scarcity. With their corrosion resistance, lightweight properties, energy efficiency, and durability, FRP materials are reshaping the landscape of desalination technology. As demands for freshwater continue to rise, leveraging innovative solutions such as FRP is critical to ensuring a sustainable and efficient water treatment future. By investing in these advanced materials, we can unlock new potentials in desalination, ultimately leading to a more water-secure world.