-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 12, 2025 21:36

Back to list

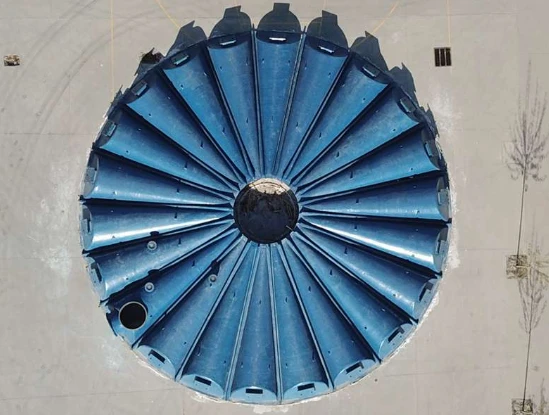

frp desalination pipes and fittings for efficient water treatment

Desalination processes are becoming crucial in the face of increasing global water scarcity, and the use of FRP (Fiber Reinforced Plastic) desalination pipes and fittings is revolutionizing this sector. Unlike traditional materials, FRP offers unique advantages for efficient water treatment systems, providing experience-backed expertise that ensures longevity and performance.

In addition, the environmental profile of FRP contributes positively to its favorability. Energy consumption in the production and transportation of FRP components is considerably lower than that of conventional materials. This reduced carbon footprint aligns with global trends towards more sustainable industrial practices. For plants aiming to minimize their ecological impact while maintaining high efficiency, FRP pipes and fittings represent an ideal solution. It’s also noteworthy that advancements in FRP technologies continue to enhance their quality and applications, driven by ongoing research and innovation in both materials science and engineering methodologies. The development of new resin systems and reinforcement techniques is continuously pushing the boundaries, resulting in even greater resistances to chemical, thermal, and mechanical stresses. It's the constant evolution in this field that upholds the authoritative aspect of FRP as a modern solution in desalination. Trustworthiness emerges from the quality assurances attached to these state-of-the-art systems. Reputable manufacturers of FRP desalination pipes and fittings adhere to stringent international standards and undergo comprehensive testing procedures to verify their product's capabilities. Such adherence to high standards ensures end-users receive products that deliver consistent, reliable performance in critical water treatment scenarios. In conclusion, FRP desalination pipes and fittings stand out in the realm of efficient water treatment due to their undeniable advantages in corrosion resistance, lightweight structure, customization potential, and robust performance. They are echoed by proven installations worldwide, backed by scientific research, and manufactured under rigorous quality controls. As the world shifts towards more sustainable and efficient water solutions, the authoritative and trustworthy nature of FRP components positions them as indispensable tools in overcoming the formidable challenge of water scarcity.

In addition, the environmental profile of FRP contributes positively to its favorability. Energy consumption in the production and transportation of FRP components is considerably lower than that of conventional materials. This reduced carbon footprint aligns with global trends towards more sustainable industrial practices. For plants aiming to minimize their ecological impact while maintaining high efficiency, FRP pipes and fittings represent an ideal solution. It’s also noteworthy that advancements in FRP technologies continue to enhance their quality and applications, driven by ongoing research and innovation in both materials science and engineering methodologies. The development of new resin systems and reinforcement techniques is continuously pushing the boundaries, resulting in even greater resistances to chemical, thermal, and mechanical stresses. It's the constant evolution in this field that upholds the authoritative aspect of FRP as a modern solution in desalination. Trustworthiness emerges from the quality assurances attached to these state-of-the-art systems. Reputable manufacturers of FRP desalination pipes and fittings adhere to stringent international standards and undergo comprehensive testing procedures to verify their product's capabilities. Such adherence to high standards ensures end-users receive products that deliver consistent, reliable performance in critical water treatment scenarios. In conclusion, FRP desalination pipes and fittings stand out in the realm of efficient water treatment due to their undeniable advantages in corrosion resistance, lightweight structure, customization potential, and robust performance. They are echoed by proven installations worldwide, backed by scientific research, and manufactured under rigorous quality controls. As the world shifts towards more sustainable and efficient water solutions, the authoritative and trustworthy nature of FRP components positions them as indispensable tools in overcoming the formidable challenge of water scarcity.

Related Products