-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp drum

Understanding FRP Drums The Advantages and Applications

Fiber Reinforced Plastic (FRP) drums are becoming increasingly popular in various industries due to their impressive properties and versatility. Composed of a polymer matrix reinforced with fibers, usually glass or carbon, these drums offer a lightweight, durable, and corrosion-resistant alternative to traditional metal or plastic drums.

Properties of FRP Drums

One of the most significant advantages of FRP drums is their exceptional strength-to-weight ratio. While they are lighter than metal counterparts, they can withstand heavy loads and resist impacts, making them ideal for shipping and storage. Additionally, FRP drums are non-corrosive, which is a crucial factor in industries dealing with harsh chemicals or extreme environmental conditions. This corrosion resistance extends the life of the drum, reducing the need for frequent replacements and ultimately saving costs.

Another key feature of FRP drums is their ability to maintain structural integrity under varying temperatures. Unlike plastic drums that may become brittle in colder temperatures or deform under heat, FRP drums can be engineered to endure a wider range of temperatures without compromising their load-bearing capabilities. This characteristic makes them suitable for use in industries that require temperature-sensitive storage and transportation.

Environmental Impact

FRP drums also demonstrate an eco-friendly profile. The durability of these drums means that they can be reused and repurposed multiple times, which reduces waste. Furthermore, modern manufacturing processes for FRP drums increasingly utilize sustainable practices, including the use of recycled materials, thereby minimizing their environmental footprint.

Applications of FRP Drums

frp drum

The versatility of FRP drums makes them suitable for numerous applications across various industries. In the chemical industry, where hazardous materials must be transported and stored safely, FRP drums excel due to their corrosion resistance and non-reactive nature. They ensure that toxic substances do not leach into the environment, providing a safe option for industry workers and surrounding communities.

In the oil and gas sector, FRP drums are favored for transporting additives and other materials that require robust containers. Their lightweight design reduces transportation costs, and their strength ensures that they endure the rigors of harsh environments, be it offshore drilling or refining facilities.

The food and beverage industry is another area where FRP drums are gaining traction. Given their resistance to contamination and ability to maintain product integrity, they are ideal for storing and transporting food ingredients and processed goods. Additionally, FRP drums can be designed to meet stringent food safety regulations, ensuring compliance with health standards.

Future Innovations and Trends

As technology advances, we can expect further innovations in the design and manufacturing of FRP drums. Researchers are exploring new fiber and resin materials that may enhance the performance of FRP drums, making them even more reliable and versatile. Additionally, the integration of smart technology in container design is an emerging trend. Sensors embedded in FRP drums could monitor conditions like temperature and pressure, providing real-time data that could significantly enhance logistics and inventory management.

Moreover, as regulations on materials and environmental impacts tighten globally, the push for sustainable packaging solutions will likely drive demand for FRP drums. Companies prioritizing eco-friendly practices will find FRP drums attractive, not only for their operational benefits but also for their alignment with corporate social responsibility goals.

Conclusion

In conclusion, FRP drums represent a significant advancement in container technology, offering an array of benefits that cater to the demands of various industries. Their lightweight, durable, and non-corrosive nature positions them as a superior alternative to traditional drums. As industries continue to evolve, the role of FRP drums will undoubtedly expand, paving the way for more sustainable and efficient practices in storage and transportation. Embracing this innovative solution is not just a smart business decision; it contributes to a more sustainable future within our rapidly changing industrial landscape.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

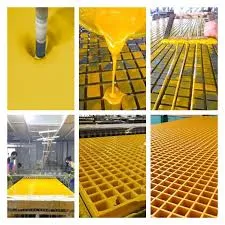

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025