-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

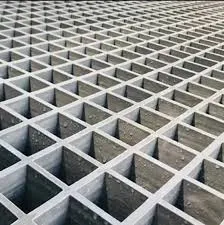

frp duct system

Understanding FRP Duct Systems A Comprehensive Overview

Fiber-Reinforced Plastic (FRP) duct systems have emerged as a vital component in the modern construction and industrial sectors due to their exceptional properties and versatility. Comprising a matrix of plastic reinforced with fibers, often made from glass, carbon, or aramid, FRP ducts offer a multitude of advantages over traditional materials such as metal and concrete.

Key Advantages of FRP Duct Systems

1. Corrosion Resistance One of the standout features of FRP duct systems is their exceptional resistance to corrosion. Unlike metal ducts that can degrade over time when exposed to moisture and various chemicals, FRP ducts maintain their structural integrity and performance in harsh environments. This makes them an ideal choice for industries like chemical processing, wastewater treatment, and coastal installations where corrosive elements are prevalent.

2. Lightweight yet Strong The lightweight nature of FRP materials significantly eases the handling, installation, and transportation processes, reducing labor costs and time. Despite their lighter weight, FRP ducts provide remarkable strength and can withstand substantial pressure and stress, ensuring longevity and reliability.

3. Thermal Insulation FRP duct systems offer superior thermal insulation properties compared to traditional materials. This is particularly beneficial in applications where temperature control is critical, such as HVAC systems. The insulation helps in maintaining desired temperatures, leading to energy savings and increased efficiency.

4. Design Flexibility FRP ducts can be manufactured in various shapes and sizes, allowing for customized solutions tailored to specific requirements. Their design flexibility enables engineers to create complex layouts that can accommodate diverse installation conditions, thereby optimizing space usage.

frp duct system

5. Environmental Benefits As sustainability becomes an increasingly important consideration in construction and manufacturing, FRP materials provide an environmentally friendly alternative. They can be produced using recycled materials and are also recyclable at the end of their lifecycle, reducing their overall environmental impact.

Applications of FRP Duct Systems

The versatility of FRP duct systems makes them applicable in a wide range of sectors. In the HVAC industry, they are commonly used for air distribution systems, leveraging their lightweight and corrosion-resistant properties to enhance efficiency and longevity. In the chemical sector, FRP ducts are utilized for the conveyance of aggressive chemicals, ensuring safety and preventing leaks through their durable construction.

Furthermore, in the field of renewable energy, FRP ducts are used in wind turbine systems, where their strength-to-weight ratio is essential for performance. Similarly, in the telecommunications industry, FRP materials find applications in the protection of cables and data lines, offering superior durability against environmental factors.

Conclusion

In summary, FRP duct systems represent a significant advancement in material technology, offering a range of benefits that address the challenges of traditional duct materials. Their corrosion resistance, lightweight nature, thermal insulation properties, design flexibility, and environmental advantages make them an attractive solution for various industries. As technology progresses and industries continue to prioritize efficiency and sustainability, the use of FRP ducts is likely to expand, paving the way for innovative applications and improved infrastructure solutions. The future of duct systems appears bright with FRP technology leading the charge towards smarter and more resilient construction practices.