-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp ductwork

Understanding FRP Ductwork A Comprehensive Overview

In modern construction and industrial applications, the efficiency of airflow systems plays a critical role in ensuring effective ventilation, temperature control, and overall energy conservation. As an innovative solution in this domain, Fiber Reinforced Polymer (FRP) ductwork has gained tremendous popularity. This article delves into what FRP ductwork is, its advantages, applications, and considerations for its use.

What is FRP Ductwork?

FRP ductwork is a system of ducts made from fiber-reinforced polymers, which are composite materials consisting of a polymer matrix reinforced with fibers. The fibers, often made of glass, carbon, or aramid, provide strength and rigidity, while the polymer component usually consists of thermosetting resins such as epoxy or polyester. This combination yields a lightweight yet incredibly strong material that is resistant to corrosion and degradation.

Advantages of FRP Ductwork

1. Corrosion Resistance One of the most significant benefits of FRP ductwork is its resistance to corrosion. Unlike traditional metal ducts, which can rust or corrode when exposed to moisture and chemicals, FRP maintains structural integrity even in harsh environments.

2. Lightweight FRP ductwork is considerably lighter than metal alternatives, making it easier to handle and install. This can result in lower transportation costs and reduced labor expenses during installation.

3. Thermal Insulation FRP offers excellent thermal insulation properties, reducing heat loss or gain within the duct system. This contributes to more stable temperatures, energy efficiency, and lower operational costs over time.

4. Customizability FRP materials can be molded into various shapes and sizes, allowing for custom designs that fit specific project requirements. This adaptability provides designers with greater flexibility in integrating ductwork into a building's architecture.

5. Low Maintenance The durability and resistance to various environmental factors mean that FRP ductwork requires less maintenance compared to conventional materials. This translates into lower long-term costs for building owners.

6. Fire Retardant Properties Many FRP composites can be manufactured to meet fire safety standards, making them suitable for applications where fire resistance is crucial.

Applications of FRP Ductwork

FRP ductwork is utilized across a wide range of industries and applications. Some key areas include

frp ductwork

- Chemical Processing Plants Due to its resistance to chemical corrosion, FRP is often employed in environments where acids and other corrosive substances are handled.

- Wastewater Treatment Facilities In these facilities, FRP ductwork can help manage odors and gases produced during sewage treatment processes without degrading from the harsh conditions.

- Food and Beverage Industry FRP duct systems are used in food processing plants, where hygiene standards are paramount. Their smooth surfaces make them easier to clean and maintain.

- HVAC Systems In commercial and residential buildings, FRP is increasingly installed in HVAC systems due to its thermal properties, which help enhance energy efficiency.

Considerations for Using FRP Ductwork

While FRP ductwork offers numerous advantages, there are important considerations to keep in mind

- Cost The initial cost of FRP ductwork can be higher than traditional materials; however, the long-term savings in maintenance and energy efficiency can offset this.

- Installation Expertise It is crucial to have experienced professionals handle the installation of FRP systems, as improper installation may lead to performance issues.

- Compatibility Ensuring that the specific type of FRP used is compatible with the intended environment, especially regarding exposure to chemicals and temperatures, is vital.

- Regulatory Compliance When used in certain applications, compliance with industry standards and regulations must be verified to ensure safety and effectiveness.

Conclusion

FRP ductwork represents a significant advancement in ventilation systems, offering unique advantages in terms of durability, efficiency, and cost-effectiveness. Its growing usage across various industries underscores its value as a versatile solution for modern construction and industrial needs. As with any material, careful consideration must be given to its application, ensuring that the benefits of FRP are fully realized in addressing the challenges of effective ductwork.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

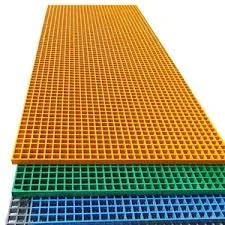

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025