-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 29, 2025 03:43

Back to list

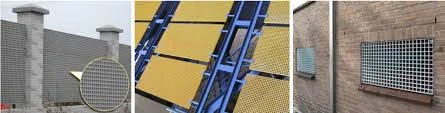

frp fan

Choosing the right type of fan for industrial applications is crucial due to the performance, cost, and environmental factors. Among the various types available, FRP (Fiberglass Reinforced Plastic) fans are increasingly becoming popular across multiple sectors. This article delves into the advantages of FRP fans and why they are an essential component for businesses aiming to optimize their operations while ensuring environmental considerations.

Moreover, FRP fans offer a lower energy consumption footprint. With their aerodynamic design capabilities, these fans enhance air movement efficiency, which directly affects power use. By decreasing electricity consumption, businesses can significantly cut operating costs while also meeting sustainability objectives. Such efficiency is increasingly important as industries face growing pressure to reduce carbon emissions and comply with global environmental standards. In terms of authority within the market, FRP fans have established a reputation backed by comprehensive field data and rigorous testing. Their widespread adoption is supported by third-party validations and industry certifications, reassuring stakeholders of their performance claims. This widespread acceptance across industries testifies to their reliability and establishes them as a tried and tested solution in challenging applications. The trustworthiness of FRP fan systems stems from their continued performance even under the harshest conditions. Many case studies highlight their ability to tackle environments with extreme temperatures and corrosive substances, outperforming traditional metal fans in longevity and efficiency. For decision-makers and engineers, such proven resilience reduces the risk associated with fan system investments. FRP fans, with their blend of durability, efficiency, and adaptability, are becoming an indispensable choice for progressive industries. They offer unique solutions that not only solve immediate operational challenges but also align with long-term strategic goals for efficiency and sustainability. As industries strive for excellence, these fans are laying the groundwork for innovative pathways in industrial airflow solutions.

Moreover, FRP fans offer a lower energy consumption footprint. With their aerodynamic design capabilities, these fans enhance air movement efficiency, which directly affects power use. By decreasing electricity consumption, businesses can significantly cut operating costs while also meeting sustainability objectives. Such efficiency is increasingly important as industries face growing pressure to reduce carbon emissions and comply with global environmental standards. In terms of authority within the market, FRP fans have established a reputation backed by comprehensive field data and rigorous testing. Their widespread adoption is supported by third-party validations and industry certifications, reassuring stakeholders of their performance claims. This widespread acceptance across industries testifies to their reliability and establishes them as a tried and tested solution in challenging applications. The trustworthiness of FRP fan systems stems from their continued performance even under the harshest conditions. Many case studies highlight their ability to tackle environments with extreme temperatures and corrosive substances, outperforming traditional metal fans in longevity and efficiency. For decision-makers and engineers, such proven resilience reduces the risk associated with fan system investments. FRP fans, with their blend of durability, efficiency, and adaptability, are becoming an indispensable choice for progressive industries. They offer unique solutions that not only solve immediate operational challenges but also align with long-term strategic goals for efficiency and sustainability. As industries strive for excellence, these fans are laying the groundwork for innovative pathways in industrial airflow solutions.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025