-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

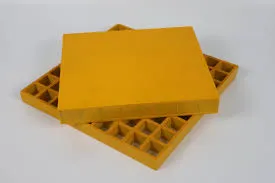

FRP Connectors for Enhanced Structural Integrity and Performance in Engineering Applications

Understanding FRP Fittings A Deep Dive into Fiber Reinforced Polymer Connections

In the realm of modern engineering and construction, the demand for innovative materials that offer strength, durability, and lightweight characteristics has led to the rising popularity of Fiber Reinforced Polymer (FRP) composites. Among the crucial components of FRP systems are FRP fittings, which play a pivotal role in assembling structures, pipelines, and various applications across industries. This article explores the importance, types, applications, and advantages of FRP fittings, showcasing their role in contemporary engineering solutions.

What are FRP Fittings?

FRP fittings are specialized connectors made from fiber-reinforced polymers, which typically include a combination of a polymer matrix reinforced with fibers such as glass, carbon, or aramid. These fittings are designed to connect sections of FRP materials, ensuring structural integrity and the ability to handle various loads and environmental conditions. They are used in applications where traditional materials may fail due to corrosion, weight, or strength limitations.

Types of FRP Fittings

FRP fittings come in several types, each designed for specific applications and requirements

1. Elbows and Tees Used to change the direction of pipes or conduits, these fittings ensure smooth flow and minimal pressure loss. 2. Flanges Serving as connection points between two segments, flanges can be bolted together or welded, providing a secure joining method for FRP components.

3. Couplings These fittings connect two ends of pipes or tubes, ensuring a tight seal to prevent leaks.

4. Reducers Utilized to connect pipes of different diameters, reducers facilitate transitions in flow systems.

5. Countersinks and Adapters These fittings allow for additional adjustments and connections, enhancing the versatility of FRP systems.

Applications of FRP Fittings

The versatility of FRP fittings enables their use in diverse sectors including

- Chemical Processing Due to their resistance to corrosive substances, FRP fittings are ideal for handling chemicals, acids, and other aggressive materials.

frp fitting

- Water and Wastewater Management FRP fittings are widely used in pipes and tanks for transporting and treating water, where their lightweight nature and corrosion resistance enhance efficiency and longevity.

- Construction In the construction sector, FRP fittings are employed in structural applications, reinforcing components in bridges, towers, and buildings, thereby reducing weight without compromising strength.

- Oil and Gas In exploration and production, FRP fittings secure pipelines and vessels, providing reliability in harsh environments where minimizing downtime is critical.

- Renewable Energy FRP fittings are increasingly finding applications in the wind and solar energy sectors, helping to create lightweight and durable structural elements.

Advantages of FRP Fittings

The advantages of using FRP fittings are numerous

1. Lightweight FRP fittings weigh significantly less than their metal counterparts, making them easier to handle and install.

2. Corrosion Resistance The inherent resistance to chemicals and environmental factors extends the lifespan of components, reducing maintenance costs over time.

3. High Strength-to-Weight Ratio FRP fittings provide superior strength without the burden of increased weight, making them ideal in structural applications.

4. Thermal Insulation FRP materials do not conduct heat as effectively as metals, reducing thermal bridging in structures.

5. Design Flexibility Manufacturers can easily mold FRP fittings into various shapes and sizes, enabling customization to meet specific project requirements.

Conclusion

As industries seek robust and innovative solutions to meet the challenges of modern engineering, FRP fittings have emerged as a vital component in a variety of applications. Their lightweight nature, corrosion resistance, and durability position them as a preferred choice over traditional materials, paving the way for a future where infrastructure can endure the test of time and environmental changes. As the technology advances and the understanding of materials improves, the role of FRP fittings will likely continue to expand, driving efficiency and resilience in numerous sectors.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025