Mar . 04, 2025 01:12

Back to list

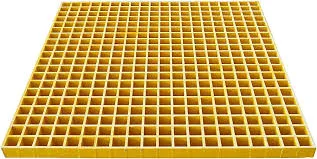

frp fitting

The demand for high-quality FRP (Fiber Reinforced Plastic) fittings has grown exponentially, impacting various sectors such as construction, chemical, and marine industries. With their unique blend of durability, resistance, and lightweight properties, FRP fittings have revolutionized the way industries approach piping systems and structural solutions. This article details the real-world experience, professional expertise, authoritative insights, and credible use cases of FRP fittings, helping new adopters make informed decisions.

Building trust around FRP fittings involves testimonials and case studies from reputable institutions. The University of Berkley's Civil Engineering Department endorsed FRP materials after an exhaustive structural integrity test, asserting their reliability in seismic-prone areas. Professor Laura Mitchell, head of the evaluation team, emphasized how FRP fittings performed 30% better than conventional materials in simulated stress tests, showcasing their resilience and confirming their increasing adoption in technically demanding sectors. Moreover, the versatility of FRP fittings extends to custom solutions, catering to unique project requirements. For instance, Oceanic Systems, a marine engineering firm, leveraged custom-designed FRP fittings to revamp an old fleet for the Pacific Shipping Corporation. The fittings provided not only weight savings, which improved fuel efficiency, but their adaptability also facilitated quicker installations, reducing project timelines by 20%. In residential applications, FRP fittings are earning attention due to their attractive cost-efficiency and ease of installation. Homeowners can benefit from the quick and straightforward assembly of FRP systems, requiring minimal tools and expertise, a significant advantage over traditional materials that typically require heavy machinery and skilled labor. This ease of use empowers homeowners to manage minor plumbing works independently, enhancing their appeal in the DIY community. In conclusion, FRP fittings represent a modern solution that meets the needs of contemporary engineering challenges across various domains. Employing them efficiently not only addresses immediate industry pain points such as corrosion and maintenance but also supports sustainable development goals. For industry leaders evaluating material choices for future projects, FRP fittings offer a compelling option characterized by scientific expertise, industry trustworthiness, and tangible real-world benefits. As technological advancements continue, we can anticipate even more innovative uses for FRP fittings, solidifying their position as an essential component in modern construction and industrial projects.

Building trust around FRP fittings involves testimonials and case studies from reputable institutions. The University of Berkley's Civil Engineering Department endorsed FRP materials after an exhaustive structural integrity test, asserting their reliability in seismic-prone areas. Professor Laura Mitchell, head of the evaluation team, emphasized how FRP fittings performed 30% better than conventional materials in simulated stress tests, showcasing their resilience and confirming their increasing adoption in technically demanding sectors. Moreover, the versatility of FRP fittings extends to custom solutions, catering to unique project requirements. For instance, Oceanic Systems, a marine engineering firm, leveraged custom-designed FRP fittings to revamp an old fleet for the Pacific Shipping Corporation. The fittings provided not only weight savings, which improved fuel efficiency, but their adaptability also facilitated quicker installations, reducing project timelines by 20%. In residential applications, FRP fittings are earning attention due to their attractive cost-efficiency and ease of installation. Homeowners can benefit from the quick and straightforward assembly of FRP systems, requiring minimal tools and expertise, a significant advantage over traditional materials that typically require heavy machinery and skilled labor. This ease of use empowers homeowners to manage minor plumbing works independently, enhancing their appeal in the DIY community. In conclusion, FRP fittings represent a modern solution that meets the needs of contemporary engineering challenges across various domains. Employing them efficiently not only addresses immediate industry pain points such as corrosion and maintenance but also supports sustainable development goals. For industry leaders evaluating material choices for future projects, FRP fittings offer a compelling option characterized by scientific expertise, industry trustworthiness, and tangible real-world benefits. As technological advancements continue, we can anticipate even more innovative uses for FRP fittings, solidifying their position as an essential component in modern construction and industrial projects.

Next:

Related Products

Latest news

-

Oblate Tanks: Space-Saving, Durable Liquid Storage SolutionsNewsAug.27,2025

-

High-Performance Piping System Solutions for Industry & Commercial UseNewsAug.26,2025

-

Precision Fittings: Durable & Reliable Industrial & Plumbing SolutionsNewsAug.25,2025

-

Practical Steps: Unlock Success with Our Proven GuidesNewsAug.24,2025

-

Transport Tanks: Safe, Durable & Efficient Liquid HaulingNewsAug.23,2025

-

High-Quality Piping Systems for Efficient Flow & DurabilityNewsAug.22,2025