-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

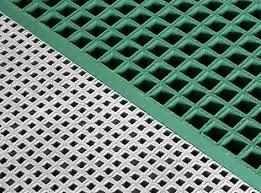

Exploring Innovative Solutions for FRP Fittings in Modern Applications

Understanding FRP Fittings A Comprehensive Guide

Fiber-reinforced plastic (FRP) fittings have revolutionized various industries by offering lightweight, durable, and corrosion-resistant solutions for numerous applications. FRP materials are composites made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This combination results in a material that possesses remarkable strength-to-weight ratios, making it an ideal choice for many demanding environments. In this article, we will explore the benefits, applications, and installation considerations related to FRP fittings.

Benefits of FRP Fittings

1. Corrosion Resistance One of the most significant advantages of FRP fittings is their excellent resistance to corrosion. Unlike traditional metal fittings, FRP does not rust or degrade when exposed to harsh chemicals, moisture, or varying environmental conditions. This makes them particularly useful in industries such as wastewater treatment, chemical processing, and marine applications.

2. Light Weight FRP fittings are significantly lighter than their metal counterparts. This reduced weight translates into lower shipping costs, easier handling during installation, and less structural support required. In many cases, this makes FRP fittings a practical choice for retrofitting projects where existing infrastructure cannot support the weight of heavier materials.

3. High Strength Despite their lightweight nature, FRP fittings boast impressive strength and durability. The fibers used in the composite enhance its structural integrity, allowing it to withstand significant mechanical stress and environmental challenges. This characteristic is crucial in applications requiring high performance under extreme conditions.

4. Versatility FRP fittings can be molded into various shapes and sizes, offering customization options that can suit specific project needs. Whether for piping systems, connectors, or joints, their adaptability makes them suitable for a wide array of applications across different industries.

5. Reduced Maintenance Because FRP fittings resist corrosion and degradation over time, they require less maintenance than traditional materials. This longevity ultimately translates into cost savings for businesses, as they will need to replace or repair fittings less frequently.

Applications of FRP Fittings

FRP fittings find extensive use in various sectors. Here are some common applications

- Chemical Processing In environments where aggressive chemicals are used, FRP fittings offer reliable performance without the risk of corrosion that comes with metal. - Water and Wastewater Management FRP fittings are employed in pipes, valves, and other components for water treatment facilities, ensuring longevity and quality in water delivery systems.

frp fittings

- Oil and Gas Industry The harsh environments characteristic of the oil and gas sector necessitate materials that can endure pressure, heat, and corrosion. FRP fittings meet these requirements effectively.

- Construction and Infrastructure Used in bridge decks, walkways, and other structures, FRP fittings contribute to the building of durable, lightweight infrastructures.

Installation Considerations

While FRP fittings offer numerous advantages, there are certain considerations to keep in mind during installation

- Proper Techniques It is essential to use the correct techniques when installing FRP fittings to prevent damage and ensure a secure fit. Training or guidance from manufacturers is recommended.

- Thermal Expansion Being a composite material, FRP fittings can expand and contract with temperature changes. Adequate design considerations should be made to accommodate these variations.

- Joining Methods Different methods for joining FRP fittings may be required depending on the specific application—such as adhesive bonding, mechanical fastening, or flanging.

- Compatibility with Other Materials When integrating FRP fittings with other materials, compatibility must be assessed to avoid corrosion or other issues.

Conclusion

FRP fittings are transforming the landscape of construction, manufacturing, and infrastructure projects. With their significant advantages—such as corrosion resistance, lightweight design, and high strength—they are becoming increasingly popular across various industries. As technology advances, the potential applications of FRP fittings will continue to expand, offering even more innovative solutions for modern challenges. Understanding these advantages and considerations is crucial for anyone looking to incorporate FRP fittings into their projects.