-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

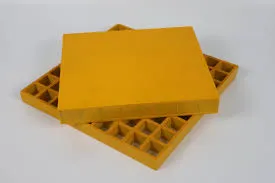

frp fittings

The Importance of FRP Fittings in Modern Industries

Fiber Reinforced Polymer (FRP) fittings have emerged as an essential component in various industries due to their unique properties and benefits. As industries strive for efficiency, durability, and cost-effectiveness, FRP fittings have become indispensable in applications ranging from construction to chemical processing. Understanding the significance of FRP fittings can help organizations make informed decisions when selecting materials for their projects.

What are FRP Fittings?

FRP fittings are components made from polymer resins reinforced with fibers, commonly glass or carbon. This composite material is designed to enhance the inherent properties of the base resin, resulting in products that boast superior strength, lightweight characteristics, resistance to corrosion, and thermal stability. Due to these properties, FRP fittings are increasingly being utilized in environments that demand high performance and resilience.

Advantages of Using FRP Fittings

1. Corrosion Resistance One of the most significant advantages of FRP materials is their resistance to chemical corrosion. Traditional materials like steel and aluminum can deteriorate quickly when exposed to harsh environments or corrosive substances. FRP fittings, however, can withstand aggressive chemicals, salty seawater, and other corrosive conditions, making them ideal for industries such as marine, wastewater treatment, and chemical processing.

2. Lightweight The lightweight nature of FRP fittings is a considerable benefit for transportation and installation. Unlike heavy metals, FRP products reduce the overall weight of constructions, which can lead to lower shipping costs and easier handling on job sites. This advantage is particularly beneficial in the aerospace and automotive industries, where every ounce saved contributes to improved fuel efficiency.

frp fittings

3. High Strength-to-Weight Ratio Despite being lightweight, FRP fittings maintain a remarkable strength-to-weight ratio. This means they can bear substantial loads without compromising on performance. Their high tensile strength makes them suitable for applications that require robust fittings, such as bridges, buildings, and other infrastructure projects.

4. Minimal Maintenance The durability of FRP fittings translates to lower maintenance costs. Traditional metal fittings often require painting or protective coatings, which can be both time-consuming and costly. In contrast, FRP components do not rust or rot, requiring minimal upkeep over their lifespan, thus allowing companies to allocate resources more effectively.

5. Versatility FRP fittings can be manufactured in various shapes and sizes, catering to a wide range of applications. They can be molded into complex designs, which allows engineers and architects to realize their visions without being constrained by the limitations of conventional materials.

Applications of FRP Fittings

FRP fittings have found their niche in numerous sectors, showcasing their versatility and effectiveness. In the construction industry, they are used for reinforcing concrete and as piping systems for hydraulic structures. In the oil and gas sector, FRP components are utilized in pipelines, tanks, and corrosion-resistant structures. The marine industry benefits from FRP fittings for boat construction and various offshore applications due to their ability to resist saltwater corrosion. Additionally, in the electrical industry, FRP fittings are used for electrical cable conduits due to their insulating properties.

Conclusion

In conclusion, the significance of FRP fittings cannot be overstated. Their combination of strength, lightweight characteristics, corrosion resistance, and minimal maintenance makes them a superior choice across various industries. As businesses continue to prioritize sustainability and efficiency, the demand for innovative materials like FRP fittings will only grow. By understanding these benefits, companies can make strategic choices that not only improve their operational performance but also lead to long-term cost savings and enhanced reliability in their projects. Whether in construction, chemical processing, or marine applications, FRP fittings prove to be a cornerstone of modern industry, paving the way for future advancements and innovations.