-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

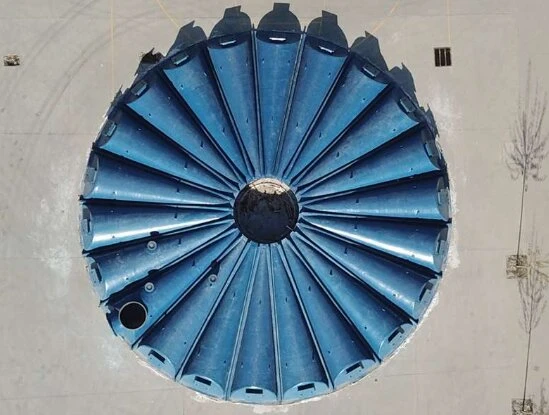

Exploring the Benefits and Applications of FRP Fittings in Modern Construction

Understanding FRP Fittings Essential Components for Modern Infrastructure

Fiber Reinforced Polymer (FRP) fittings are increasingly becoming indispensable in various industries, especially in construction and infrastructure projects. These fittings, made from a composite material that strengthens a polymer matrix with fibrous substances like glass or carbon, are renowned for their superior strength, durability, and resistance to corrosion. In this article, we will delve into the unique properties, advantages, and applications of FRP fittings, as well as their growing importance in today's world.

Properties of FRP Fittings

One of the defining characteristics of FRP fittings is their exceptional mechanical properties. They are lightweight yet incredibly strong, allowing them to withstand heavy loads without the risk of fracture. This is particularly crucial in construction, where materials must support substantial weights while maintaining structural integrity. Moreover, FRP fittings exhibit impressive resistance to environmental factors, including chemicals, moisture, and extreme temperatures. This resistance makes them ideal for use in harsh environments, such as waste treatment plants or offshore applications.

Additionally, FRP fittings have a high fatigue resistance, which means they can endure repetitive stress without degrading over time. This feature is essential for applications that involve dynamic loading conditions, such as bridges and industrial machinery. The insulating properties of FRP also provide thermal and electrical insulation, making them safer to use in various applications.

Advantages of Using FRP Fittings

The adoption of FRP fittings comes with a multitude of benefits that cater to the demands of modern industries. Firstly, their lightweight nature reduces transportation and installation costs, as less manpower and machinery are required to handle the components. This cost-effectiveness is a significant advantage in large-scale projects.

frp fittings

Secondly, FRP fittings require minimal maintenance due to their corrosion-resistant properties. Unlike traditional materials like metal, which may corrode over time, FRP remains intact, leading to lower life-cycle costs. This long-term durability not only saves money but also contributes to sustainability, as less frequent replacements mean reduced waste.

Furthermore, FRP fittings offer design flexibility. They can be molded into complex shapes to suit different applications, allowing engineers to innovate without the limitations posed by traditional materials. This adaptability has made them a preferred choice in industries ranging from construction to aerospace.

Applications of FRP Fittings

FRP fittings find applications across various sectors. In the construction industry, they are used for a wide range of purposes, including pipes, valves, and tanks. Their corrosion resistance makes them especially suited for chemical processing plants and wastewater treatment facilities, where they handle aggressive substances.

In the energy sector, FRP fittings are utilized in wind turbine manufacturing and renewable energy applications due to their lightweight properties, which help improve overall efficiency. Additionally, these fittings are finding their place in transportation infrastructure, such as bridges and roadways, where their strength-to-weight ratio can enhance performance and longevity.

Conclusion

As industries evolve and the need for sustainable, efficient materials grows, FRP fittings are poised to play a crucial role in shaping modern infrastructure. Their unique properties, coupled with numerous advantages, make them a compelling choice for a variety of applications. Embracing these advanced materials not only supports the development of resilient structures but also contributes to more sustainable practices across multiple sectors. As we continue to innovate and overcome engineering challenges, FRP fittings will undoubtedly remain at the forefront of material science and engineering technology.