-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 15, 2025 13:31

Back to list

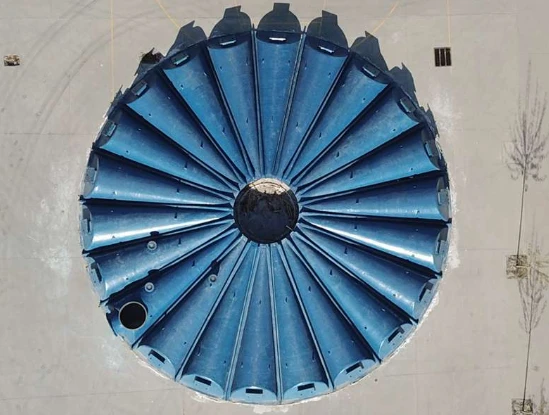

frp flange and blind

FRP (Fiber Reinforced Plastic) flanges and blinds are rapidly becoming essential components in industries ranging from chemical processing to water treatment due to their unique properties and advantages over traditional materials. These components are recognized for their corrosion resistance, lightweight nature, and high strength, making them highly desirable in environments where traditional metal flanges and blinds might fail.

The versatility of FRP flanges and blinds is further evidenced by their adaptability to custom requirements. Manufacturers can fabricate these components to specific dimensions and specifications tailored to unique industrial needs. This flexibility in design not only allows for seamless integration into existing systems but also accommodates future expansions and modifications with ease. The growing demand for environmentally sustainable solutions has further propelled the adoption of FRP flanges and blinds. Their manufacturing process is less energy-intensive compared to traditional metals, and the materials used are often recyclable, aligning with modern environmental policies and initiatives. By incorporating FRP components, industries can not only achieve their operational goals but also adhere to stringent environmental regulations. Quality assurance is a pivotal aspect when selecting FRP flanges and blinds. Ensuring that these components meet industry standards and certifications is crucial for operational safety and efficiency. Working with reputable manufacturers who provide detailed product specifications, testing certifications, and proven track records of delivering high-quality FRP components is vital for maintaining trust and reliability in industrial applications. In conclusion, FRP flanges and blinds offer a modern solution to numerous industrial challenges posed by traditional materials. Their corrosion resistance, durability, customizable features, and environmental benefits position them as a superior choice for any industry looking to optimize performance while reducing costs. As technology advances and industry demands evolve, FRP components are set to play an ever-increasing role in the future of industrial equipment and infrastructure. Their application promises not only operational excellence but also a commitment to sustainable practices, making them a valuable investment for long-term success.

The versatility of FRP flanges and blinds is further evidenced by their adaptability to custom requirements. Manufacturers can fabricate these components to specific dimensions and specifications tailored to unique industrial needs. This flexibility in design not only allows for seamless integration into existing systems but also accommodates future expansions and modifications with ease. The growing demand for environmentally sustainable solutions has further propelled the adoption of FRP flanges and blinds. Their manufacturing process is less energy-intensive compared to traditional metals, and the materials used are often recyclable, aligning with modern environmental policies and initiatives. By incorporating FRP components, industries can not only achieve their operational goals but also adhere to stringent environmental regulations. Quality assurance is a pivotal aspect when selecting FRP flanges and blinds. Ensuring that these components meet industry standards and certifications is crucial for operational safety and efficiency. Working with reputable manufacturers who provide detailed product specifications, testing certifications, and proven track records of delivering high-quality FRP components is vital for maintaining trust and reliability in industrial applications. In conclusion, FRP flanges and blinds offer a modern solution to numerous industrial challenges posed by traditional materials. Their corrosion resistance, durability, customizable features, and environmental benefits position them as a superior choice for any industry looking to optimize performance while reducing costs. As technology advances and industry demands evolve, FRP components are set to play an ever-increasing role in the future of industrial equipment and infrastructure. Their application promises not only operational excellence but also a commitment to sustainable practices, making them a valuable investment for long-term success.

Next:

Related Products