-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Designs for FRP Fuel Tank Solutions and Their Applications

Understanding FRP Fuel Tanks Innovation in Fuel Storage

In the world of fuel storage solutions, the choice of materials plays a crucial role in ensuring safety, durability, and efficiency. One of the most promising innovations in this field is the use of Fiber Reinforced Plastic (FRP) for fuel tanks. FRP materials are increasingly being favored across various industries for their unique properties, which can significantly enhance the performance of fuel storage systems.

What is FRP?

FRP is a composite material made from a polymer matrix reinforced with fibers. These fibers can be made from materials such as glass, carbon, or aramid, significantly improving the mechanical properties of the composite. When it comes to fuel tanks, FRP offers numerous advantages over traditional materials such as metal and concrete.

Advantages of FRP Fuel Tanks

1. Corrosion Resistance One of the most significant advantages of FRP fuel tanks is their exceptional resistance to corrosion. Unlike metal tanks that can rust and degrade over time due to exposure to various chemicals and environmental conditions, FRP tanks are highly durable and resist chemical attack. This feature not only extends the lifespan of the tank but also ensures the integrity of the fuel stored within.

2. Lightweight Design FRP is considerably lighter than steel or concrete, making it easier to transport and install. The reduced weight is particularly beneficial for applications where space and load-bearing capacity may be limited. This lightweight characteristic can lead to lower transportation costs and simplified installation processes.

3. Structural Strength While lightweight, FRP tanks do not compromise on strength. The composite structure provides excellent tensile strength and resistance to impact, making FRP tanks ideal for harsh environments where they may be subjected to physical stress.

4. Tailored Flexibility FRP can be manufactured in various shapes and sizes to meet specific needs. This flexibility allows for custom solutions tailored to particular storage requirements, whether for large-scale industrial use or smaller, localized applications.

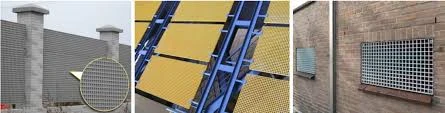

frp fuel tank

5. Thermal Insulation Fuel tanks made from FRP have better thermal insulation properties compared to conventional materials, helping to maintain the temperature of the stored fuel. This characteristic can be particularly important for fuels that are sensitive to temperature fluctuations, thereby enhancing their stability and performance.

Applications of FRP Fuel Tanks

The applications for FRP fuel tanks are diverse, spanning across multiple industries. They are increasingly being used in transportation, aviation, marine, and renewable energy sectors. In the aviation industry, for instance, FRP tanks are utilized for fuel storage due to their lightweight properties, which contribute to overall aircraft efficiency.

In addition, the renewable energy sector has begun to adopt FRP technology for biofuel storage, where the benefits of corrosion resistance and durability can significantly enhance the lifecycle of storage systems. Furthermore, as sustainability becomes a vital component of industrial operations, the long lifespan and low maintenance needs of FRP tanks align with eco-friendly practices.

Future Prospects

As technology progresses and the demand for efficient fuel storage solutions continues to rise, the future of FRP fuel tanks looks promising. Advancements in manufacturing techniques and composite materials will likely lead to even better performance characteristics and wider acceptance across various sectors. Additionally, growing environmental regulations may further drive the adoption of FRP tanks, as industries seek safer, more sustainable alternatives for fuel storage.

Conclusion

In conclusion, FRP fuel tanks represent a significant advancement in the field of fuel storage, combining durability, efficiency, and safety. Their unique properties make them an attractive choice for a variety of applications, providing solutions that meet the needs of modern industries. As we continue to explore the full potential of FRP materials, it is evident that they will play a crucial role in shaping the future of fuel storage technology.