-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp grating

Understanding Fiber-Reinforced Polymer Grating A Comprehensive Overview

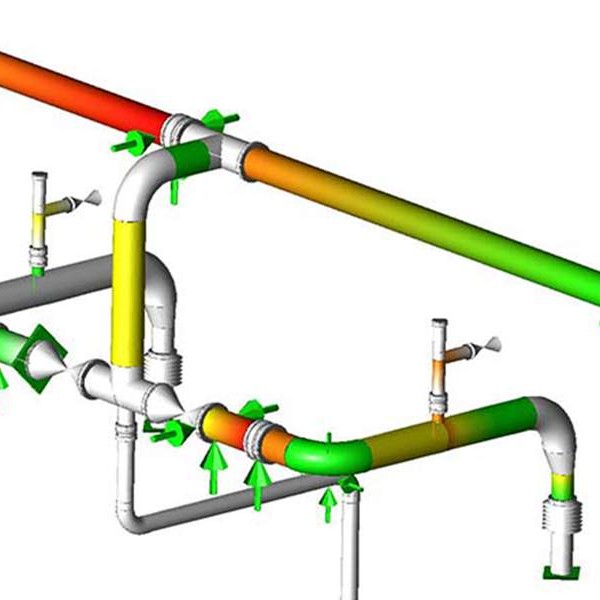

Fiber-Reinforced Polymer (FRP) grating has emerged as a vital technology in various engineering and construction applications due to its unique properties. This article delves into the fundamental aspects of FRP grating, its benefits, applications, and the reasons behind its growing popularity across industries.

What is FRP Grating?

FRP grating refers to a composite material formed by combining a polymer matrix with fiber reinforcements, typically glass, carbon, or aramid fibers. This combination results in a lightweight, high-strength material with excellent resistance to corrosion, making it an ideal choice for environments that would degrade traditional materials like steel or wood.

Benefits of FRP Grating

1. Corrosion Resistance One of the standout features of FRP grating is its remarkable resistance to corrosive elements. Unlike metals, which can rust or corrode when exposed to moisture, chemicals, or harsh environmental conditions, FRP grating maintains its integrity over time. This makes it particularly desirable in chemical plants, wastewater treatment facilities, and coastal applications.

2. Lightweight and Easy Installation FRP grating is significantly lighter than steel grating, which simplifies transportation and installation. This lightweight characteristic reduces labor costs and allows for easier manipulation on-site, making it ideal for projects where weight is a critical factor.

frp grating

3. Durability and Strength Despite its lightness, FRP grating offers exceptional structural integrity. It can withstand heavy loads and impacts, making it suitable for industrial settings that demand robust materials. Additionally, the material's resistance to UV radiation ensures longevity, even when exposed to direct sunlight.

4. Safety Features FRP grating often comes with slip-resistant surfaces, enhancing safety in environments where wet surfaces are common. This feature is crucial in preventing workplace accidents, particularly in sectors like food processing, pharmaceuticals, and marine applications.

Applications of FRP Grating

The versatility of FRP grating has led to its adoption in a wide range of applications. In the construction industry, it is often used for walkways, platforms, and stair treads. In industrial settings, it is ideal for making ladders and access platforms due to its strength and durability. Additionally, FRP grating plays a crucial role in the marine industry, where its corrosion resistance is vital for docks, bridges, and waterfront structures.

In the environmental sector, FRP grating is commonly used in water treatment plants and chemical processing facilities. Its ability to withstand harsh chemicals and environments makes it a reliable choice for systems dealing with aggressive substances.

Conclusion

Fiber-Reinforced Polymer grating represents a significant advancement in material science, combining strength, lightweight properties, and resistance to environmental degradation. As industries continue to seek durable, cost-effective, and safe alternatives to traditional materials, FRP grating is poised to play an increasingly important role in construction and engineering. With ongoing innovations and improvements, the future of FRP grating is set for expansive growth, making it an exciting area to watch as we move forward.