-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

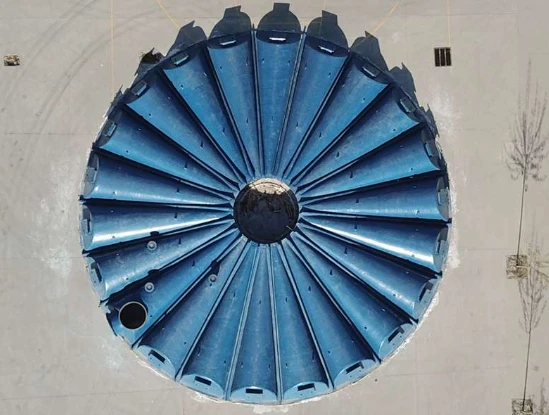

Exploring the Benefits and Applications of FRP Hoods in Modern Industries

The Importance of FRP Hoods in Modern Engineering

In the realm of modern engineering, material selection plays a crucial role in the design and functionality of various components. One such innovation is the use of Fiber Reinforced Polymer (FRP) hoods, which have emerged as a popular choice in numerous applications ranging from automotive to industrial equipment. FRP hoods offer a combination of strength, lightweight properties, and corrosion resistance, making them an ideal solution for many demanding environments.

Understanding FRP

FRP is a composite material made by combining a polymer matrix with reinforcing fibers. The fibers, typically glass, carbon, or aramid, provide increased structural integrity, while the polymer matrix binds everything together and protects the fibers from environmental factors. This unique combination results in a material that boasts remarkable tensile strength and rigidity, but remains significantly lighter than traditional materials like steel or aluminum.

Benefits of FRP Hoods

One of the most significant advantages of FRP hoods is their weight-to-strength ratio. For industries such as automotive, reducing the overall weight of vehicles can lead to improved fuel efficiency and enhanced performance. By substituting heavier materials with FRP, manufacturers can create lighter, more efficient designs without compromising on durability.

Additionally, FRP hoods are highly resistant to corrosion, which is critical in environments where components are exposed to harsh chemicals or extreme weather conditions. Traditional metal hoods are often vulnerable to rust, leading to deterioration and failure over time. In contrast, FRP hoods maintain their integrity even in the most challenging conditions, offering a longer lifespan and reduced maintenance costs.

Aesthetic Versatility

frp hood

Beyond performance characteristics, FRP hoods also provide aesthetic versatility. They can be manufactured in various colors and finishes, allowing engineers and designers to customize the appearance of the product without the need for additional coatings or paint. This aesthetic flexibility is particularly beneficial in the automotive industry, where aesthetics play a significant role in consumer choice.

Applications in Various Industries

FRP hoods are proving to be invaluable in different sectors. In the automotive industry, manufacturers frequently use FRP hoods for their lightweight properties and aerodynamic designs. Race cars, in particular, utilize FRP due to its ability to withstand high speeds and potential impacts while enabling significant weight savings.

In the aerospace industry, where every ounce matters, FRP components help in the design of lightweight and fuel-efficient aircraft. The use of FRP allows for the production of complex shapes that traditional materials struggle to achieve, thus contributing to better aerodynamic efficiency.

Industrial applications are also reaping the benefits of FRP hoods. Electrical enclosures, chemical storage tanks, and equipment covers often employ FRP materials to ensure durability while minimizing the risk of corrosion and wear.

Conclusion

As the demand for efficient, durable, and light-weight components continues to rise, FRP hoods will undoubtedly play a pivotal role in shaping the future of engineering. Their combination of strength, corrosion resistance, and design flexibility makes them an exceptional choice across various industries. As technology advances and the manufacturing processes for FRP improve, it is likely that we will see an even broader adoption of FRP hoods, further revolutionizing the way we approach design and functionality in engineering. The future is bright for FRP, and its applications are boundless.