-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

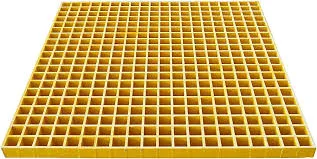

frp insulated storage vessel

The Importance of FRP Insulated Storage Vessels

In contemporary industrial applications, the storage and management of various materials require specialized solutions to ensure safety, efficiency, and sustainability. One such advancement is the use of Fiber Reinforced Polymer (FRP) insulated storage vessels. These innovative structures are gaining prominence across various sectors due to their unique properties and advantages over traditional materials.

The Importance of FRP Insulated Storage Vessels

One of the primary benefits of FRP insulated storage vessels is their excellent thermal insulation capabilities. Insulation is critical in maintaining the desired temperature of the stored materials, significantly reducing thermal losses. This is particularly beneficial in processes where temperature control is vital, helping to preserve the integrity and longevity of the stored products. By minimizing energy consumption, FRP vessels contribute to a more sustainable operational model, aligning with global efforts toward reducing carbon footprints.

frp insulated storage vessel

Another advantage of FRP vessels is their exceptional resistance to environmental factors. Unlike traditional materials such as steel or concrete, FRP does not corrode when exposed to harsh chemicals or saline environments. This feature extends the lifespan of the storage vessels, reduces maintenance costs, and ensures safe storage conditions for hazardous materials. Industries dealing with corrosive substances, including oil and gas, wastewater treatment, and chemical production, find FRP vessels particularly advantageous.

Furthermore, the lightweight nature of FRP allows for easier transportation and installation compared to heavier materials. This characteristic not only facilitates logistics but also reduces the structural demands on the supports and foundations, potentially lowering overall project costs.

The versatility of FRP insulated storage vessels is another compelling reason for their increasing adoption. They can be custom-designed to meet specific requirements, including size, shape, and insulation thickness, making them suitable for a wide range of applications from small-scale operations to large industrial complexes.

In conclusion, FRP insulated storage vessels represent a significant advancement in storage technology, offering a combination of durability, efficiency, and safety. As industries continue to seek sustainable and cost-effective solutions, the demand for these innovative vessels is likely to grow. The transition to FRP technology not only enhances operational efficiency but also aligns with broader environmental goals, ensuring that we are better equipped to handle the challenges of modern storage needs. With continuous advancements in materials science, FRP vessels promise to play an integral role in the future of storage solutions.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025