-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

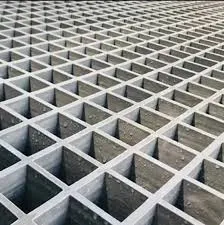

frp insulated storage vessel

FRP Insulated Storage Vessel A Sustainable Solution for Modern Industries

In the quest for sustainable and efficient storage solutions, the use of Fiber Reinforced Polymer (FRP) insulated storage vessels has emerged as a game-changer in various industrial applications. These advanced vessels combine the unique properties of FRP with superior insulation capabilities, making them an ideal choice for storing liquids, gases, and other materials under varying environmental conditions.

What is FRP?

Fiber Reinforced Polymer (FRP) is a composite material made from a polymer matrix reinforced with fibers, such as glass or carbon. The combination of these materials results in a lightweight, strong, and corrosion-resistant product. FRP has gained popularity in various industries, including chemical processing, food and beverage, water treatment, and waste management.

Insulation Properties

One of the standout features of FRP insulated storage vessels is their excellent thermal insulation properties. Traditional storage tanks are often prone to heat transfer, leading to temperature fluctuations that can affect the quality of the stored contents. In contrast, FRP insulated vessels maintain a stable temperature and minimize heat loss, making them particularly beneficial for temperature-sensitive materials.

Energy Efficiency

In today’s fast-paced industrial environment, energy efficiency is a top priority. FRP insulated storage vessels not only reduce energy consumption associated with heating and cooling systems but also contribute to lower operational costs. By maintaining the ideal temperature of stored materials, these vessels allow for more efficient processing and use of energy resources.

frp insulated storage vessel

Corrosion Resistance

Corrosion is a significant concern for many industries, particularly when it comes to storing aggressive chemicals or substances. FRP’s resistance to corrosive environments ensures a longer lifespan for storage vessels, leading to reduced maintenance costs and increased safety. This durability makes FRP a suitable choice for applications in highly corrosive environments, such as chemical manufacturing and wastewater treatment.

Customization and Versatility

FRP insulated storage vessels can be tailored to meet specific storage needs. They can be designed in various shapes and sizes, enabling companies to optimize their storage space according to operational requirements. Additionally, the customizable nature of FRP allows manufacturers to produce vessels that can withstand specific pressures and temperatures, further enhancing their versatility.

Environmental Benefits

In an increasingly eco-conscious world, the environmental impact of industrial operations is under scrutiny. FRP insulated storage vessels contribute to sustainability efforts by reducing energy consumption, minimizing waste, and decreasing the carbon footprint associated with traditional storage solutions. Moreover, FRP is recyclable, aligning with waste reduction goals and promoting a circular economy.

Conclusion

As industries strive for greater efficiency, sustainability, and safety, FRP insulated storage vessels stand out as a promising solution. Their exceptional insulation properties, energy efficiency, corrosion resistance, and versatility make them ideal for a wide range of applications. As technology advances and the demand for innovative storage solutions grows, FRP continues to pave the way for a more sustainable and efficient future in industrial storage. By embracing these modern vessels, companies can not only enhance their operational performance but also contribute positively to environmental conservation.